Table of Contents

أهمية بطانة الجودة في إنتاج الأحذية: دليل للمصنعين

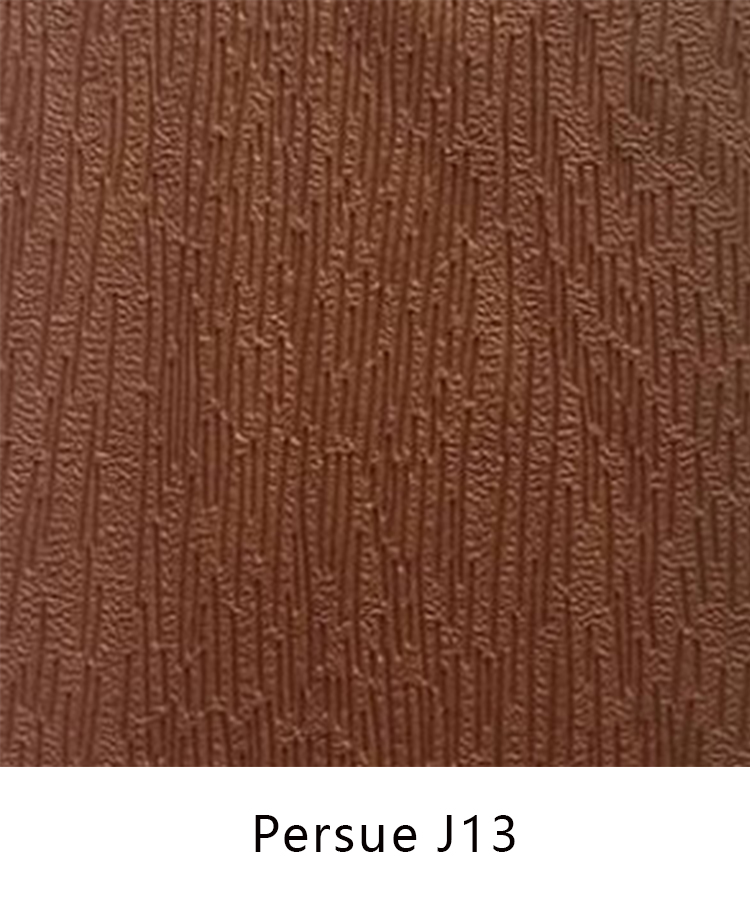

المنتج

استخدام

| بطانة داخلية للحذاء | أحذية,حقائب، ملابس |

| مواد وتقنيات مبتكرة لتبطين الأحذية الفائق: تعزيز الراحة والمتانة | علاوة على ذلك، أصبحت الاستدامة محورًا رئيسيًا في صناعة الأحذية، مما دفع المصنعين إلى استكشاف بدائل صديقة للبيئة لبطانات الأحذية. يتم استخدام المواد المعاد تدويرها، مثل زجاجات PET والألياف المستصلحة، لإنشاء بطانات لا تقدم فوائد الأداء فحسب، بل تقلل أيضًا من التأثير البيئي لإنتاج الأحذية. بالإضافة إلى ذلك، تكتسب المواد الحيوية المشتقة من مصادر متجددة قوة جذب كبدائل مستدامة للبطانات الاصطناعية التقليدية.

مع تزايد وعي المستهلك فيما يتعلق بالآثار البيئية والأخلاقية لقرارات الشراء الخاصة بهم، تستثمر العلامات التجارية بشكل متزايد في الممارسات المستدامة عبر سلاسل التوريد الخاصة بها. بما في ذلك مصادر وإنتاج بطانات الأحذية. من خلال إعطاء الأولوية للمواد الصديقة للبيئة وعمليات التصنيع، يمكن للشركات جذب المستهلكين المهتمين بالبيئة والمساهمة في جهود الاستدامة المستمرة في صناعة الأحذية. في الختام، أدى تطور المواد والتقنيات المستخدمة في إنتاج بطانة الأحذية إلى تحسينات كبيرة في الراحة والمتانة والاستدامة. من المواد الاصطناعية والبناء السلس إلى تقنيات تحسين الأداء والبدائل الصديقة للبيئة، يسعى مصنعو الأحذية باستمرار إلى تحسين جودة وأداء بطانات الأحذية. ونتيجة لذلك، يمكن للمستهلكين أن يتوقعوا أحذية لا تبدو أنيقة فحسب، بل تشعر أيضًا بالراحة، وتدوم لفترة أطول، وتتوافق مع قيمهم فيما يتعلق بالمسؤولية البيئية. |

In conclusion, quality lining is a crucial aspect of shoe production that should not be overlooked by manufacturers. Investing in materials and processes that prioritize comfort, support, durability, and aesthetics can lead to higher customer satisfaction, increased brand loyalty, and ultimately, greater success in the competitive footwear market. By understanding the importance of quality lining and incorporating it into their production practices, manufacturers can ensure that their shoes not only look good but also feel good to wear, delivering a superior experience for consumers.

Innovative Materials and Techniques for Superior Shoe Lining: Enhancing Comfort and Durability

In the realm of footwear manufacturing, every detail counts, from the outer design to the inner construction. One often-overlooked aspect crucial to both comfort and durability is the lining of shoes. While it may seem like a minor component, the lining plays a significant role in enhancing the overall quality of footwear. In recent years, the industry has witnessed a surge in innovative materials and techniques aimed at improving shoe linings, providing consumers with superior comfort and durability.

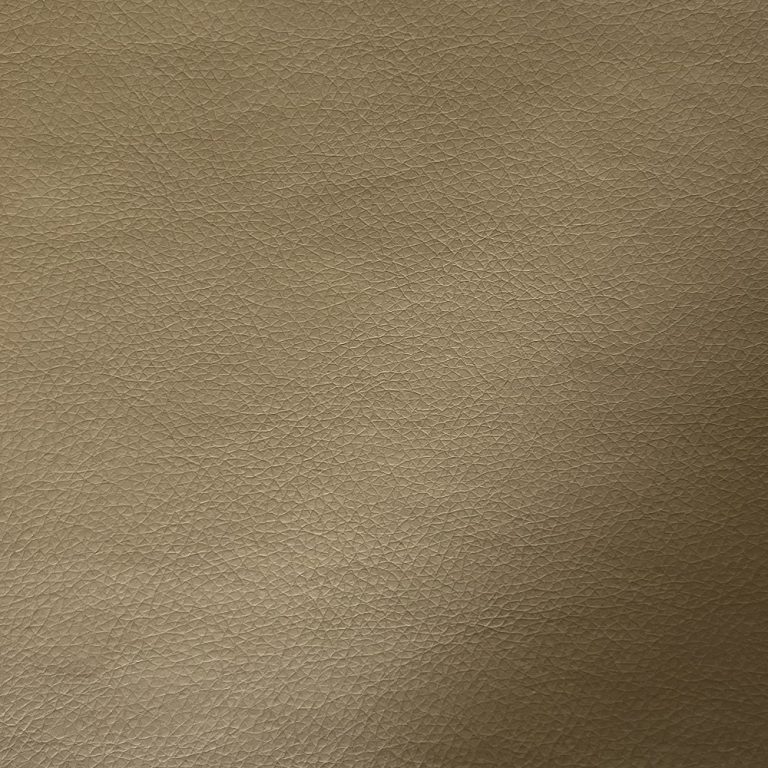

Traditionally, shoe linings were primarily made from natural materials such as leather and textile fabrics. While these materials offer certain benefits, such as breathability and flexibility, they also come with limitations in terms of durability and moisture-wicking properties. As consumer expectations evolve and demands for higher performance increase, footwear manufacturers have turned to cutting-edge materials and techniques to meet these requirements.

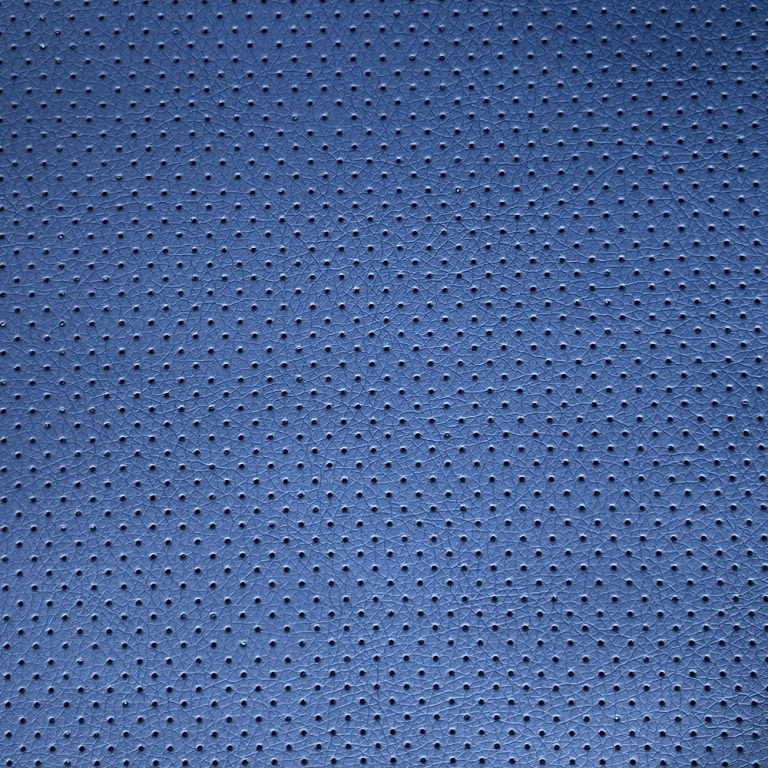

One of the most notable advancements in shoe lining production is the use of synthetic materials engineered specifically for footwear applications. Synthetic linings offer several advantages over traditional materials, including enhanced durability, moisture management, and breathability. Materials like microfiber and mesh fabrics are lightweight, flexible, and resistant to wear and tear, making them ideal choices for lining shoes intended for rigorous activities or long-term wear.

Moreover, advancements in manufacturing techniques, such as seamless construction and 3D printing, have revolutionized the way shoe linings are produced. Seamless construction eliminates the need for stitching, reducing the risk of irritation and friction points inside the shoe. This not only enhances comfort but also improves the overall aesthetics of the footwear. Additionally, 3D printing allows for precise customization of shoe linings, ensuring a perfect fit and optimal performance for each individual wearer.

Another area of innovation in shoe lining production is the integration of performance-enhancing technologies. Companies are incorporating features such as moisture-wicking treatments, antimicrobial agents, and cushioning systems directly into the lining materials. These technologies help manage moisture and odor, prevent bacterial growth, and provide extra support and comfort where needed, resulting in a more comfortable and hygienic wearing experience.

Furthermore, sustainability has become a key focus in the footwear industry, prompting manufacturers to explore eco-friendly alternatives for shoe linings. Recycled materials, such as PET bottles and reclaimed fibers, are being utilized to create linings that not only offer performance benefits but also reduce the environmental impact of footwear production. Additionally, bio-based materials derived from renewable sources are gaining traction as sustainable alternatives to traditional synthetic linings.

As consumer awareness grows regarding the environmental and ethical implications of their purchasing decisions, brands are increasingly investing in sustainable practices throughout their supply chains, including the sourcing and production of shoe linings. By prioritizing eco-friendly materials and manufacturing processes, companies can appeal to environmentally conscious consumers and contribute to the ongoing sustainability efforts within the footwear industry.

In conclusion, the evolution of materials and techniques used in shoe lining production has led to significant improvements in comfort, durability, and sustainability. From synthetic materials and seamless construction to performance-enhancing technologies and eco-friendly alternatives, footwear manufacturers are continuously striving to enhance the quality and performance of shoe linings. As a result, consumers can expect footwear that not only looks stylish but also feels comfortable, lasts longer, and aligns with their values regarding environmental responsibility.