Table of Contents

Popular Bookbinding Techniques Used in PU Factory

Bookbinding is a centuries-old craft that involves the art of binding together pages to create a book. In recent years, there has been a resurgence in the popularity of bookbinding, with many people opting for custom-made books that reflect their personal style and taste. One popular technique used in bookbinding is the use of polyurethane (PU) in the manufacturing process.

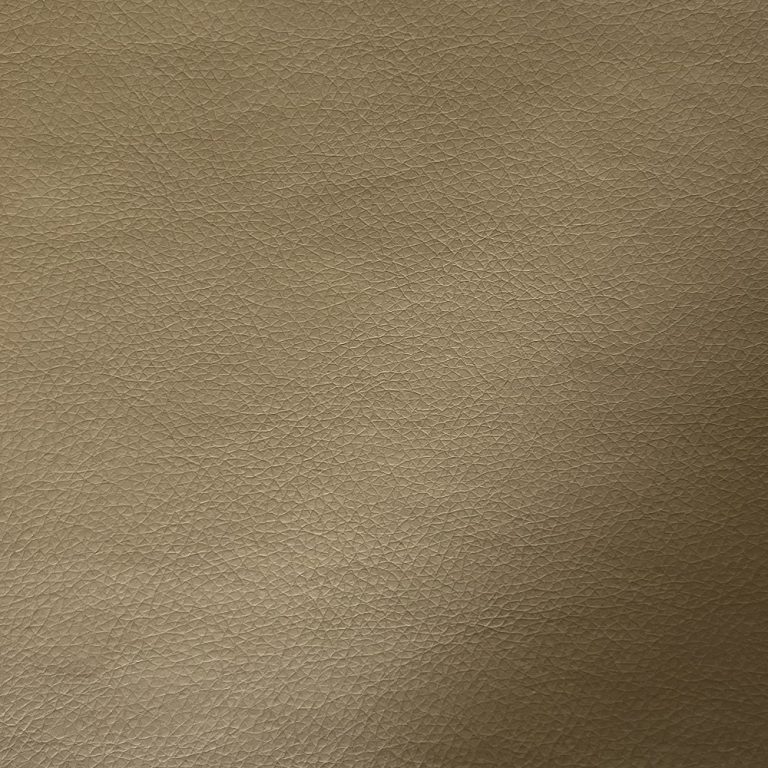

PU is a versatile material that is commonly used in bookbinding due to its durability and flexibility. It is also known for its ability to mimic the look and feel of leather, making it a popular choice for those looking for a high-quality finish. In a PU factory, skilled craftsmen use a variety of techniques to create beautiful and long-lasting books that are sure to stand the test of time.

One of the most common techniques used in a PU factory is hot stamping. This involves using a heated die to press a design or logo onto the cover of the book. The heat from the die transfers the design onto the PU, creating a permanent and elegant finish. Hot stamping is a popular choice for those looking to add a touch of sophistication to their books, as it can be used to create intricate designs and patterns that are sure to impress.

Another popular technique used in a PU factory is embossing. This involves creating a raised design on the cover of the book by pressing a metal die into the PU. The result is a textured and tactile finish that adds depth and interest to the book. Embossing is a great way to add a touch of luxury to a book, as it can be used to create a variety of effects, from simple patterns to intricate designs.

In addition to hot stamping and embossing, PU factories also use techniques such as foil stamping and debossing to create unique and eye-catching books. Foil stamping involves using a heated die to transfer a thin layer of metallic foil onto the cover of the book, creating a shiny and reflective finish. Debossing, on the other hand, involves pressing a design into the PU to create a sunken effect. Both techniques are popular choices for those looking to add a touch of glamour to their books.

Overall, the techniques used in a PU factory are designed to create beautiful and long-lasting books that are sure to impress. Whether you are looking for a simple and elegant design or a more intricate and detailed finish, a PU factory can help bring your vision to life. With skilled craftsmen and a variety of techniques at their disposal, PU factories are able to create books that are not only visually stunning but also durable and practical. So if you are looking for a high-quality bookbinding solution, consider choosing a PU factory for your next project.

How to Choose the Right Materials for Bookbinding in a PU Factory

Bookbinding is a meticulous craft that requires attention to detail and the use of high-quality materials. In a PU factory, choosing the right materials for bookbinding is crucial to ensure the durability and aesthetic appeal of the finished product. There are several factors to consider when selecting materials for bookbinding, including the type of book being bound, the desired look and feel of the finished product, and the budget constraints of the project.

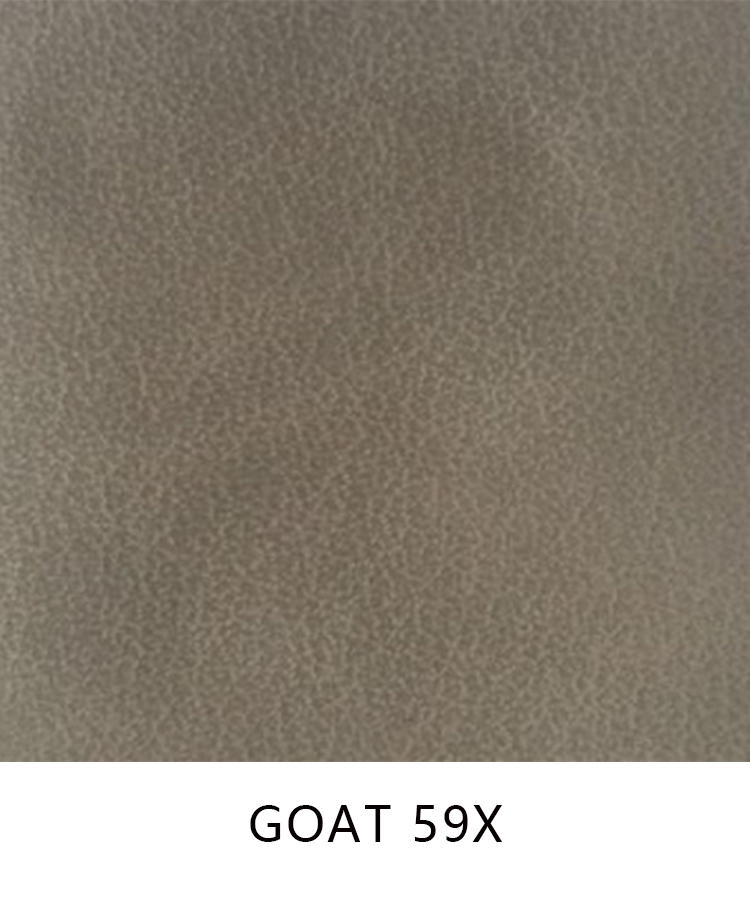

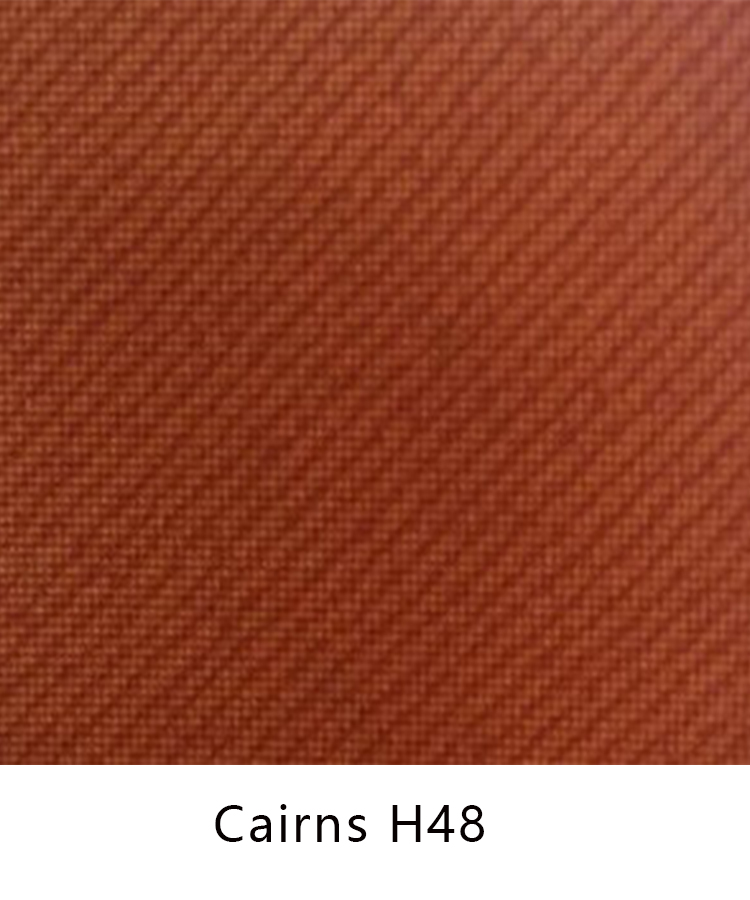

One of the most important materials to consider when bookbinding in a PU factory is the cover material. The cover material not only provides protection for the pages inside the book but also sets the tone for the overall look and feel of the finished product. When choosing a cover material, it is important to consider factors such as durability, flexibility, and aesthetic appeal. PU leather is a popular choice for bookbinding in a PU factory due to its durability, flexibility, and wide range of colors and textures available.

In addition to the cover material, the paper used for the pages inside the book is also an important consideration. The type of paper used can impact the overall quality and feel of the finished product. When choosing paper for bookbinding in a PU factory, it is important to consider factors such as weight, texture, and color. High-quality paper with a smooth finish is often preferred for bookbinding, as it provides a clean and professional look to the finished product.

Another important material to consider when bookbinding in a PU factory is the adhesive used to bind the pages together. The adhesive plays a crucial role in ensuring that the pages stay securely bound together over time. It is important to choose an adhesive that is strong, flexible, and long-lasting. PU factories often use specialized adhesives that are designed specifically for bookbinding, ensuring a secure and durable bond between the pages.

| Sort | Article Name |

| S | Notebook leather |

When selecting materials for bookbinding in a PU factory, it is also important to consider any additional embellishments or decorations that may be added to the finished product. This could include features such as foil stamping, embossing, or debossing. These embellishments can add a touch of elegance and sophistication to the finished product, but it is important to choose materials that are compatible with the chosen cover material and adhesive.

In conclusion, choosing the right materials for bookbinding in a PU factory is essential to creating a high-quality and visually appealing finished product. By considering factors such as cover material, paper, adhesive, and embellishments, bookbinders can ensure that their finished products meet the highest standards of quality and durability. With careful consideration and attention to detail, bookbinders can create beautiful and long-lasting books that will be treasured for years to come.