Table of Contents

Popular Bookbinding Techniques Used by PU Manufacturers

Bookbinding is a crucial aspect of the publishing industry, as it not only protects the content of a book but also enhances its aesthetic appeal. Polyurethane (PU) manufacturers play a significant role in the bookbinding process by providing high-quality materials that are durable and visually appealing. In this article, we will explore some popular bookbinding techniques used by PU manufacturers to create stunning and long-lasting books.

One of the most common bookbinding techniques used by PU manufacturers is perfect binding. Perfect binding involves gluing the pages of a book to the spine, creating a clean and professional finish. This technique is often used for paperback books and magazines, as it is cost-effective and allows for easy customization. PU manufacturers use high-quality adhesives to ensure that the pages are securely bound together, creating a durable and long-lasting book.

Another popular bookbinding technique used by PU manufacturers is case binding. Case binding involves attaching a hardcover to the book block, providing added protection and a more luxurious feel. PU manufacturers use a variety of materials for the cover, including PU leather, to create a visually appealing and durable finish. Case binding is often used for high-end books, such as coffee table books and collector’s editions, as it adds a touch of elegance and sophistication.

Saddle stitching is another bookbinding technique commonly used by PU manufacturers. Saddle stitching involves stapling the pages of a book together along the spine, creating a simple and cost-effective finish. This technique is often used for booklets, brochures, and magazines, as it allows for easy assembly and a clean, professional look. PU manufacturers use high-quality staples and adhesives to ensure that the pages are securely bound together, creating a neat and polished final product.

Wire-O binding is a popular bookbinding technique used by PU manufacturers for creating notebooks, calendars, and other stationery items. Wire-O binding involves inserting a metal wire through small holes punched along the edge of the pages, creating a sturdy and flexible finish. PU manufacturers use high-quality wires and binding machines to ensure that the pages are securely bound together, allowing for easy flipping and writing. Wire-O binding is a versatile and practical option for creating functional and stylish stationery items.

In conclusion, PU manufacturers play a crucial role in the bookbinding process by providing high-quality materials and expertise to create stunning and long-lasting books. Whether using perfect binding, case binding, saddle stitching, or Wire-O binding, PU manufacturers ensure that the final product is durable, visually appealing, and professionally finished. By utilizing these popular bookbinding techniques, PU manufacturers help publishers and authors bring their stories to life in a beautiful and tangible form.

How to Choose the Right PU Manufacturer for Your Bookbinding Needs

When it comes to bookbinding, choosing the right PU manufacturer is crucial to ensuring the quality and durability of your finished product. PU, or polyurethane, is a versatile material that is commonly used in bookbinding due to its strength, flexibility, and aesthetic appeal. With so many manufacturers to choose from, it can be overwhelming to find the right one for your specific needs. In this article, we will discuss some key factors to consider when selecting a PU manufacturer for your bookbinding project.

One of the first things to consider when choosing a PU manufacturer is the quality of their materials. It is important to work with a manufacturer that uses high-quality PU materials that are durable and long-lasting. This will ensure that your finished product will stand the test of time and maintain its appearance and functionality for years to come. Look for a manufacturer that has a reputation for producing high-quality PU materials and has a track record of delivering consistent results.

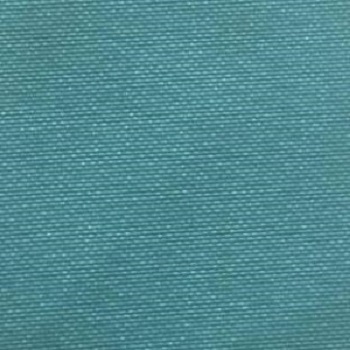

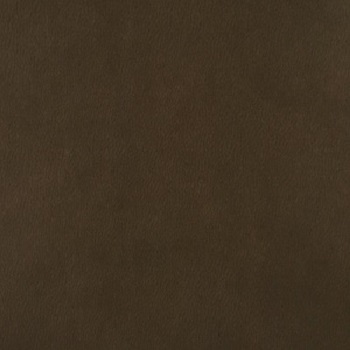

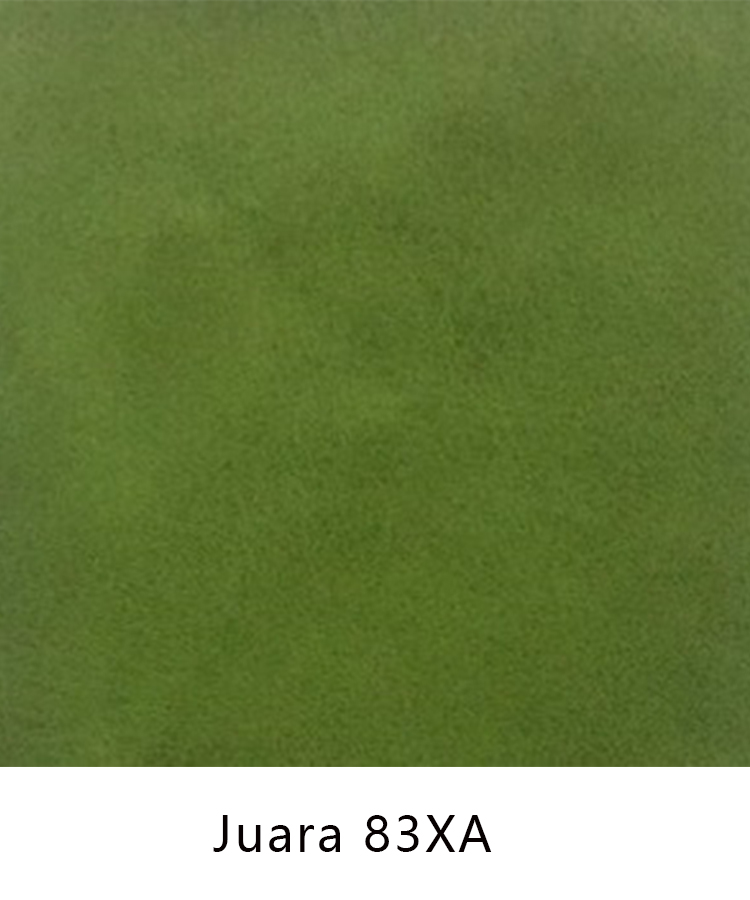

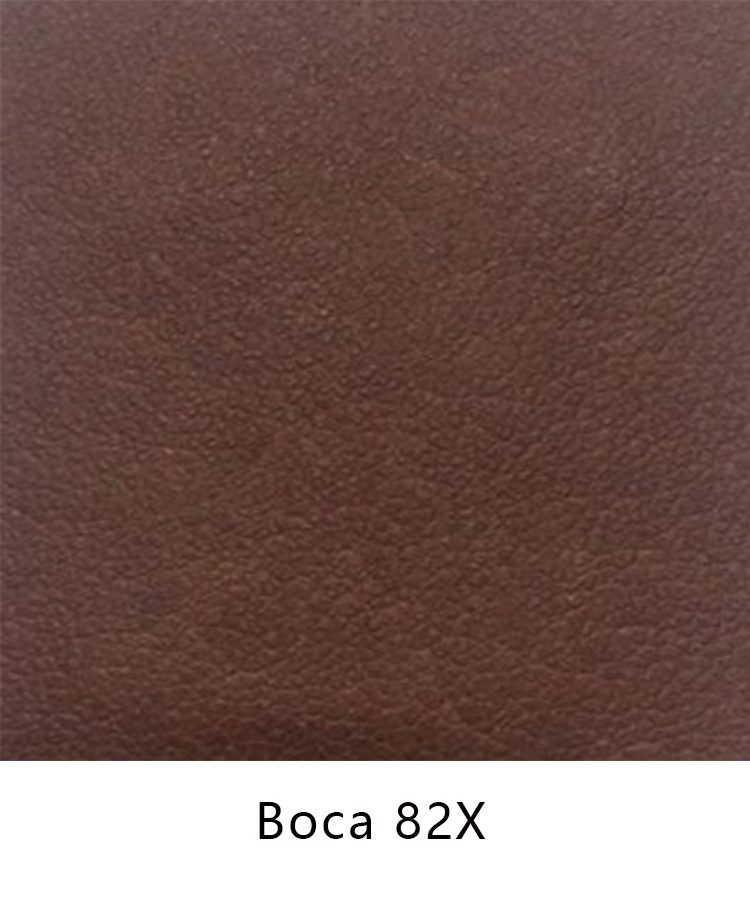

In addition to the quality of the materials, it is also important to consider the manufacturer’s production capabilities. Make sure that the manufacturer has the equipment and expertise to handle your specific bookbinding needs. Whether you require custom sizes, colors, or finishes, it is important to work with a manufacturer that can accommodate your unique requirements. Ask about the manufacturer’s production process and capabilities to ensure that they can meet your expectations and deliver a finished product that meets your specifications.

Another important factor to consider when choosing a PU manufacturer is their experience and expertise in the bookbinding industry. Look for a manufacturer that has a proven track record of producing high-quality PU products for bookbinding applications. A manufacturer with years of experience and a deep understanding of the bookbinding process will be able to provide valuable insights and recommendations to help you achieve the best results for your project. Ask for samples of their previous work and inquire about their experience working with other clients in the bookbinding industry.

When selecting a PU manufacturer, it is also important to consider their customer service and communication. A manufacturer that is responsive, attentive, and easy to work with will make the bookbinding process smoother and more efficient. Look for a manufacturer that is willing to listen to your needs and provide personalized solutions to help you achieve your bookbinding goals. Communication is key when working with a manufacturer, so make sure that they are easy to reach and quick to respond to any questions or concerns you may have.

| Article Name | Use |

| Notebook pu | Notebook |

In conclusion, choosing the right PU manufacturer for your bookbinding needs is a critical decision that can impact the quality and success of your project. Consider factors such as the quality of the materials, production capabilities, experience and expertise, and customer service when selecting a manufacturer. By taking the time to research and evaluate potential manufacturers, you can ensure that your bookbinding project is a success and that your finished product meets your expectations. Remember to communicate openly and clearly with your chosen manufacturer to ensure that they understand your needs and can deliver a product that exceeds your expectations.