Table of Contents

Production Process of Yoga Mat PU Factory

Yoga has become a popular form of exercise and relaxation for many people around the world. With the increasing demand for yoga mats, manufacturers are constantly looking for ways to improve their production processes to meet the needs of their customers. One such production process is the use of polyurethane (PU) in the manufacturing of yoga mats.

PU is a versatile material that is commonly used in the production of various products, including yoga mats. It is known for its durability, flexibility, and comfort, making it an ideal material for yoga mats. The production process of yoga mat PU factory involves several steps to ensure the quality and performance of the final product.

The first step in the production process of a yoga mat PU factory is the selection of high-quality PU materials. The raw materials used in the production of PU yoga mats are carefully chosen to meet the specific requirements of the product. These materials are then processed and mixed together to create a uniform and consistent material that will be used to make the yoga mats.

Once the raw materials are prepared, they are then poured into molds to create the desired shape and size of the yoga mats. The molds are carefully designed to ensure that the yoga mats are of the highest quality and meet the specifications of the customers. The molds are then placed in a press where they are heated and compressed to form the final shape of the yoga mats.

After the yoga mats are formed, they are then trimmed and finished to remove any excess material and ensure a smooth and even surface. The yoga mats are then inspected for quality control to ensure that they meet the standards set by the factory. Any defects or imperfections are corrected before the yoga mats are packaged and shipped to customers.

The production process of a yoga mat PU factory also involves the use of advanced technology and machinery to ensure the efficiency and accuracy of the manufacturing process. Automated machines are used to mix, pour, and mold the materials, reducing the risk of human error and ensuring a consistent and high-quality product.

In addition to the production process, the yoga mat PU factory also focuses on sustainability and environmental responsibility. The factory uses eco-friendly materials and processes to minimize waste and reduce its carbon footprint. By using sustainable practices, the factory is able to produce high-quality yoga mats that are not only good for the environment but also for the health and well-being of its customers.

In conclusion, the production process of a yoga mat PU factory involves several steps to ensure the quality and performance of the final product. From the selection of high-quality materials to the use of advanced technology and sustainable practices, the factory is committed to producing yoga mats that meet the needs of its customers. By focusing on quality, efficiency, and sustainability, the yoga mat PU factory is able to provide customers with durable and comfortable yoga mats that enhance their yoga practice.

Benefits of Using PU Yoga Mats

Yoga has become a popular form of exercise and relaxation for many people around the world. With its focus on mindfulness, flexibility, and strength, yoga offers a wide range of physical and mental benefits. One essential tool for practicing yoga is a yoga mat, which provides cushioning and support during poses and helps prevent slipping on the floor. While there are many types of yoga mats available on the market, one material that has gained popularity in recent years is polyurethane, or PU.

PU yoga mats are made from a synthetic material that offers several advantages over traditional rubber or PVC mats. One of the main benefits of PU yoga mats is their durability. PU is a strong and resilient material that can withstand regular use without wearing out or losing its shape. This means that a PU yoga mat will last longer than other types of mats, making it a cost-effective investment for yoga practitioners.

Another advantage of PU yoga mats is their superior grip. PU is a non-slip material that provides excellent traction, even when wet. This means that you can practice yoga with confidence, knowing that your mat will stay in place and support you during challenging poses. The grip of a PU yoga mat can also help improve your alignment and stability, allowing you to focus on your practice without worrying about slipping or sliding.

In addition to durability and grip, PU yoga mats are also easy to clean and maintain. Unlike traditional rubber mats, which can absorb sweat and odors, PU mats can be wiped clean with a damp cloth and mild soap. This makes it easy to keep your mat fresh and hygienic, even after intense yoga sessions. PU mats are also lightweight and portable, making them convenient for travel or taking to yoga classes.

One of the unique features of PU yoga mats is their eco-friendly properties. PU is a recyclable material that is free from harmful chemicals such as phthalates and heavy metals. This makes PU yoga mats a sustainable choice for environmentally conscious yogis who want to reduce their carbon footprint. By choosing a PU yoga mat, you can support sustainable manufacturing practices and contribute to a healthier planet.

Overall, PU yoga mats offer a range of benefits that make them an excellent choice for yoga practitioners of all levels. From their durability and grip to their easy maintenance and eco-friendly properties, PU mats provide a comfortable and supportive surface for practicing yoga. Whether you are a beginner or an experienced yogi, investing in a high-quality PU yoga mat can enhance your practice and help you achieve your fitness goals.

In conclusion, the benefits of using a PU yoga mat are clear. With its durability, grip, easy maintenance, and eco-friendly properties, a PU mat is a versatile and practical choice for anyone looking to improve their yoga practice. By choosing a PU yoga mat, you can enjoy a comfortable and supportive surface for your practice while also supporting sustainable manufacturing practices. So why wait? Upgrade your yoga mat to a PU mat today and experience the difference for yourself.

Sustainability Practices in Yoga Mat PU Factory

Yoga has become a popular form of exercise and relaxation for many people around the world. With the increasing demand for yoga mats, manufacturers are constantly looking for ways to produce these mats in a sustainable and environmentally friendly manner. One such way is through the use of polyurethane (PU) in the production process.

PU is a versatile material that is commonly used in the manufacturing of yoga mats due to its durability and cushioning properties. However, the production of PU can have negative environmental impacts if not done responsibly. This is why many yoga mat PU factories are implementing sustainability practices to reduce their carbon footprint and minimize waste.

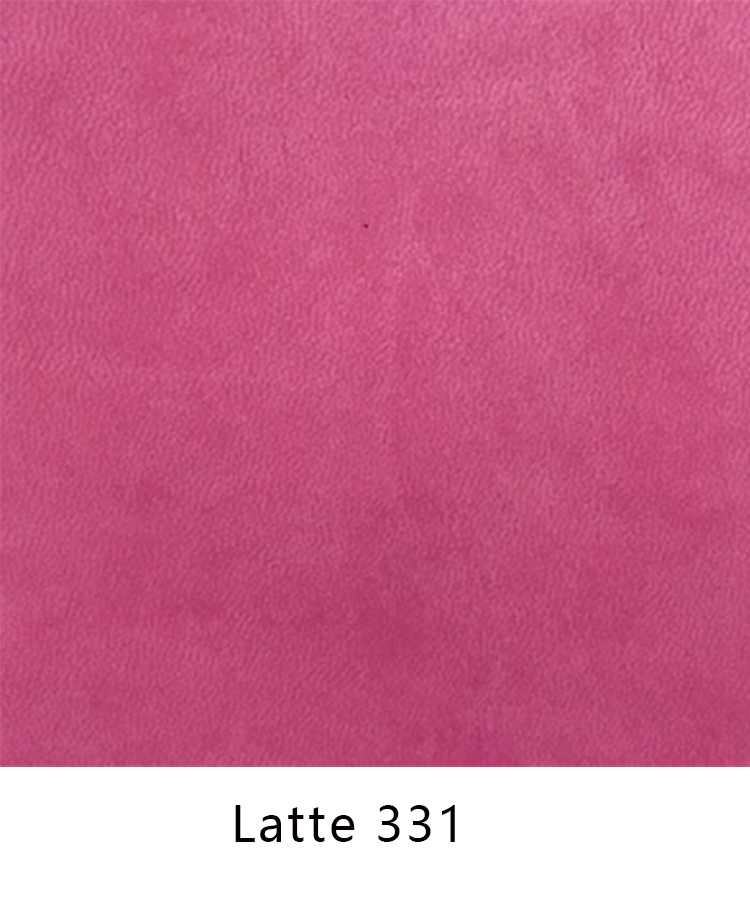

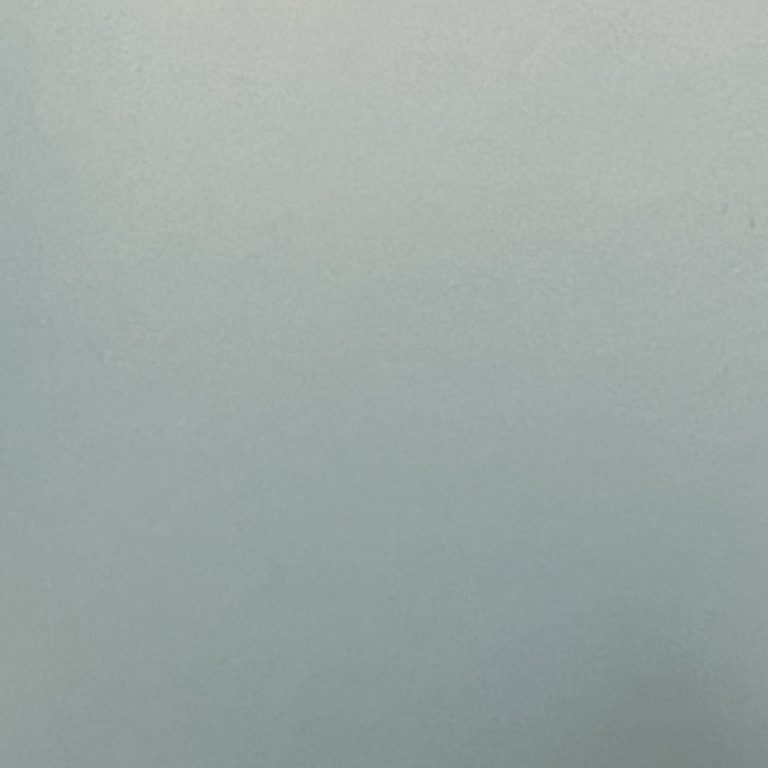

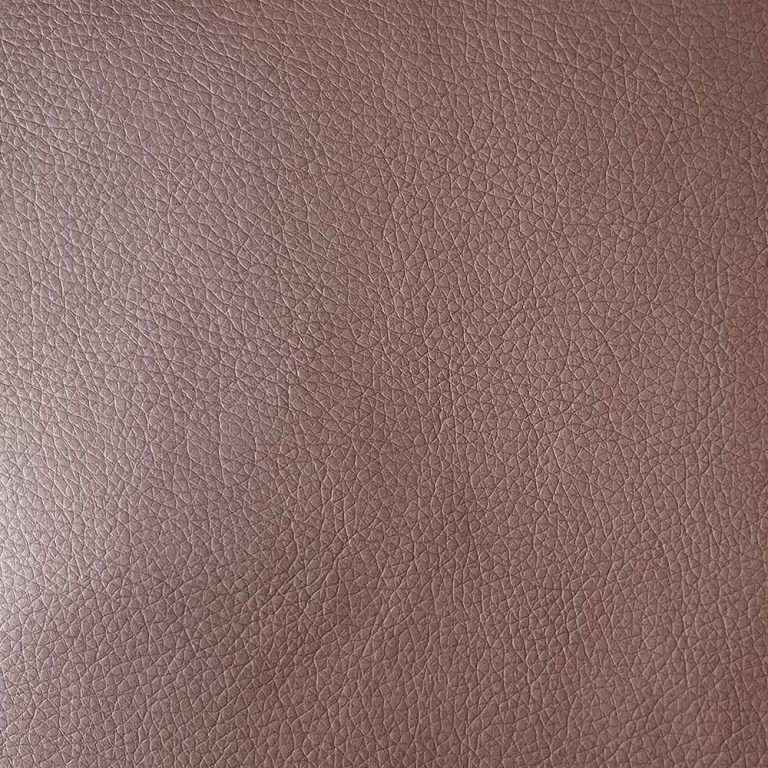

| Commodity Name | Yoga mat rubber and pu leather |

| Amount | 1 |

One of the key sustainability practices in a yoga mat PU factory is the use of recycled materials. By incorporating recycled PU into the production process, manufacturers can reduce the amount of virgin materials needed, thus conserving natural resources and reducing waste. This not only helps to lower the environmental impact of the factory but also promotes a circular economy where materials are reused and recycled rather than disposed of.

In addition to using recycled materials, yoga mat PU factories are also implementing energy-efficient practices to reduce their overall energy consumption. This can include using energy-efficient machinery, optimizing production processes to minimize energy waste, and investing in renewable energy sources such as solar or wind power. By reducing their energy consumption, factories can lower their greenhouse gas emissions and lessen their impact on the environment.

Furthermore, many yoga mat PU factories are focusing on waste reduction and recycling initiatives. This can involve implementing a waste management system to properly sort and recycle materials, as well as finding innovative ways to repurpose waste products. For example, some factories may use leftover PU scraps to create new products or donate them to organizations that can use them for other purposes. By reducing waste and promoting recycling, factories can minimize their environmental footprint and contribute to a more sustainable future.

Another important sustainability practice in yoga mat PU factories is ensuring ethical labor practices. This includes providing fair wages and safe working conditions for employees, as well as promoting diversity and inclusion within the workforce. By prioritizing the well-being of their workers, factories can create a positive work environment and build a strong, motivated team that is dedicated to producing high-quality, sustainable products.

Overall, sustainability practices in yoga mat PU factories are essential for reducing the environmental impact of production and promoting a more sustainable industry. By using recycled materials, implementing energy-efficient practices, reducing waste, and ensuring ethical labor practices, factories can create high-quality yoga mats that are both durable and environmentally friendly. As the demand for sustainable products continues to grow, it is important for manufacturers to prioritize sustainability in their production processes and lead the way towards a more sustainable future for the yoga industry.