Table of Contents

Pros and Cons of Using PU Leather in Furniture Manufacturing

When it comes to furniture manufacturing, one of the most popular materials used is PU leather. PU leather, also known as polyurethane leather, is a synthetic material that is designed to look and feel like real leather. It is made by applying a layer of polyurethane to a base material, such as polyester or cotton, to create a durable and versatile material that is often used in furniture upholstery.

There are several advantages to using PU leather in furniture manufacturing. One of the main benefits is its affordability. PU leather is typically much cheaper than genuine leather, making it a cost-effective option for manufacturers looking to produce high-quality furniture at a lower price point. Additionally, PU leather is easy to clean and maintain, as it is resistant to stains and spills. This makes it a practical choice for furniture that is used frequently and may be exposed to spills or messes.

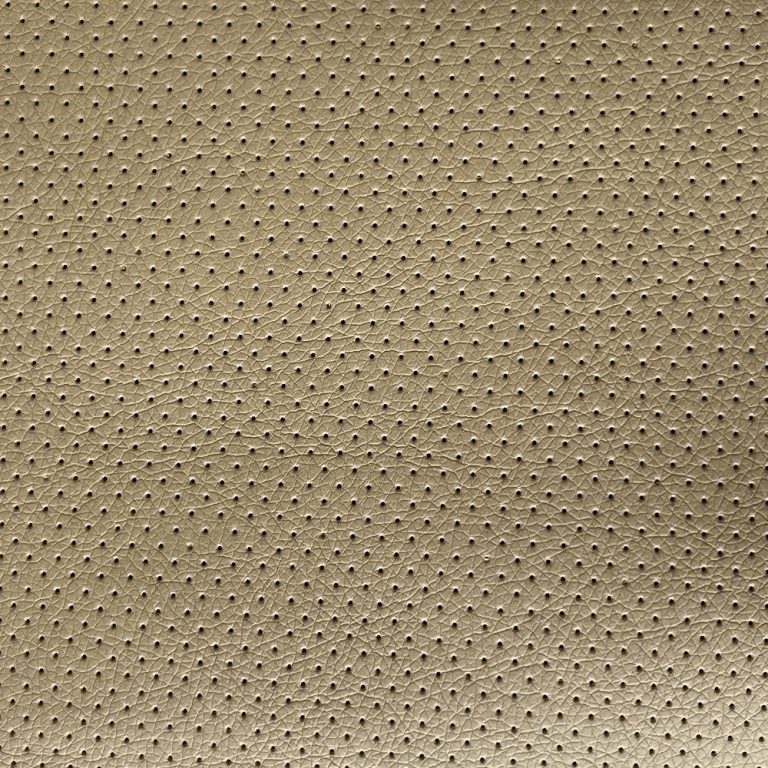

Another advantage of using PU leather in furniture manufacturing is its versatility. PU leather can be dyed in a wide range of colors and finishes, allowing manufacturers to create furniture in a variety of styles and designs. Additionally, PU leather is available in different textures, from smooth and glossy to matte and textured, giving manufacturers the flexibility to create furniture that suits a range of aesthetic preferences.

Despite its many advantages, there are some drawbacks to using PU leather in furniture manufacturing. One of the main disadvantages is its durability. While PU leather is designed to be durable and long-lasting, it is not as strong or resilient as genuine leather. Over time, PU leather may show signs of wear and tear, such as cracking or peeling, especially in high-traffic areas.

Another drawback of using PU leather in furniture manufacturing is its environmental impact. PU leather is a synthetic material that is made from petroleum-based chemicals, which can have a negative impact on the environment. Additionally, the production of PU leather can release harmful chemicals into the air and water, contributing to pollution and environmental degradation.

In conclusion, there are both pros and cons to using PU leather in furniture manufacturing. While PU leather is affordable, easy to clean, and versatile, it may not be as durable or environmentally friendly as genuine leather. Ultimately, the decision to use PU leather in furniture manufacturing will depend on the specific needs and priorities of the manufacturer. By weighing the advantages and disadvantages of PU leather, manufacturers can make an informed decision about whether or not to use this material in their furniture production.

How to Choose the Right PU Manufacturer for Your Furniture Business

When it comes to running a furniture business, choosing the right PU manufacturer is crucial. PU, or polyurethane, is a versatile material that is commonly used in the production of furniture due to its durability, comfort, and aesthetic appeal. However, not all PU manufacturers are created equal, and selecting the right one can make a significant difference in the quality of your products and the success of your business.

| No. | Article Name |

| 1 | PU leather fabric for sofa |

One of the first things to consider when choosing a PU manufacturer is their experience and expertise in the industry. Look for a manufacturer that has a proven track record of producing high-quality PU products for furniture. A manufacturer with years of experience will likely have the knowledge and skills necessary to meet your specific requirements and deliver products that meet your standards.

In addition to experience, it is important to consider the manufacturer’s reputation in the industry. Look for reviews and testimonials from other furniture businesses that have worked with the manufacturer in the past. A manufacturer with a good reputation is more likely to provide reliable and consistent products and services, which can help you build trust with your customers and grow your business.

Another important factor to consider when choosing a PU manufacturer is their production capabilities. Make sure the manufacturer has the capacity to meet your production needs and deadlines. Consider factors such as production volume, lead times, and flexibility in order to ensure that the manufacturer can accommodate your business requirements.

Cost is also an important consideration when choosing a PU manufacturer. While it is important to find a manufacturer that offers competitive pricing, it is equally important to consider the overall value that the manufacturer provides. Look for a manufacturer that offers a balance of quality and affordability, and be wary of manufacturers that offer significantly lower prices than their competitors, as this may indicate lower quality products.

Communication is key when working with a PU manufacturer. Make sure the manufacturer is responsive to your inquiries and provides clear and timely communication throughout the production process. A manufacturer that is easy to work with and keeps you informed of any updates or changes can help ensure a smooth and successful partnership.

Finally, consider the manufacturer’s commitment to sustainability and ethical practices. Look for a manufacturer that prioritizes environmental responsibility and ethical labor practices in their production processes. Choosing a manufacturer that aligns with your values can help you build a positive brand image and appeal to environmentally conscious consumers.

In conclusion, choosing the right PU manufacturer for your furniture business is a critical decision that can impact the quality of your products and the success of your business. Consider factors such as experience, reputation, production capabilities, cost, communication, and sustainability when evaluating potential manufacturers. By taking the time to research and select a reputable and reliable manufacturer, you can ensure that your furniture business thrives and grows in the competitive market.