Pros and Cons of Using PU Base Material in Production

Polyurethane (PU) is a versatile material that has become increasingly popular in various industries due to its unique properties. As a PU base material producer, it is important to understand the pros and cons of using PU in production to make informed decisions about its application.

| No. | Products |

| 1 | Leather base fabric |

One of the main advantages of using PU as a base material is its durability. PU is known for its high resistance to wear and tear, making it an ideal choice for products that are subjected to heavy use or harsh conditions. This durability ensures that products made with PU base material have a longer lifespan, reducing the need for frequent replacements and ultimately saving costs in the long run.

In addition to its durability, PU is also highly flexible and can be molded into a wide range of shapes and sizes. This versatility makes PU a popular choice for manufacturers looking to create products with intricate designs or complex structures. Whether it is used in furniture, footwear, or automotive parts, PU base material can be easily customized to meet specific requirements, allowing for greater design flexibility and creativity.

Furthermore, PU is a lightweight material, which can be advantageous in industries where weight is a critical factor. Products made with PU base material are lighter in weight compared to those made with traditional materials, making them easier to transport and handle. This can be particularly beneficial in industries such as aerospace or automotive, where reducing weight can lead to improved fuel efficiency and performance.

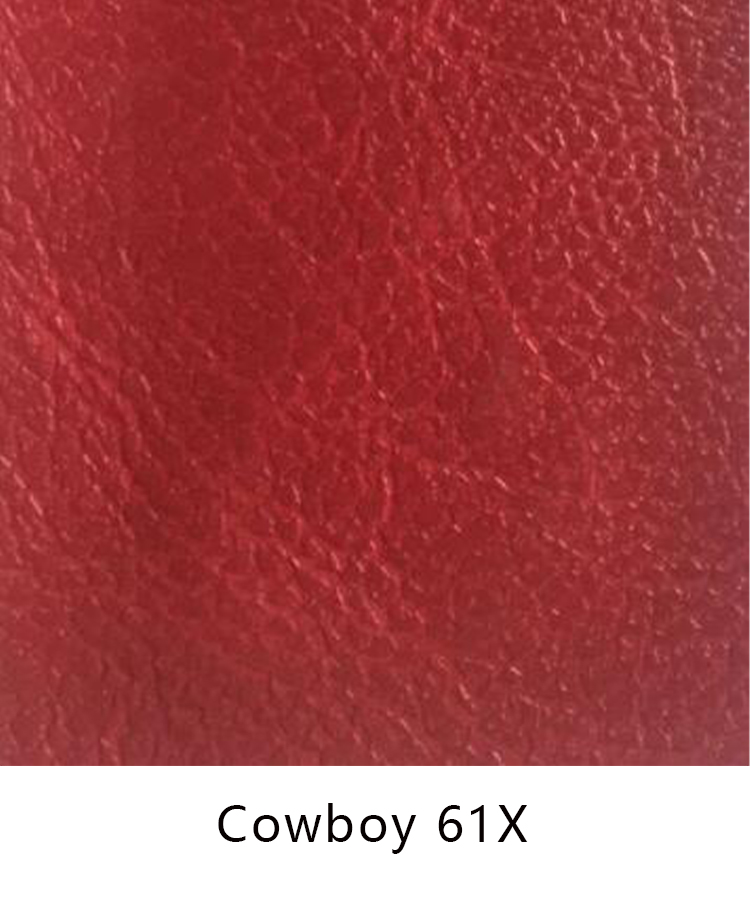

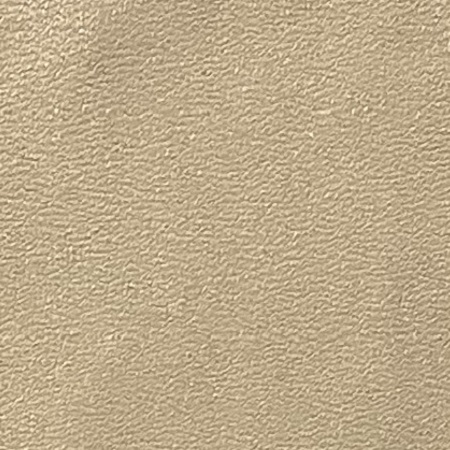

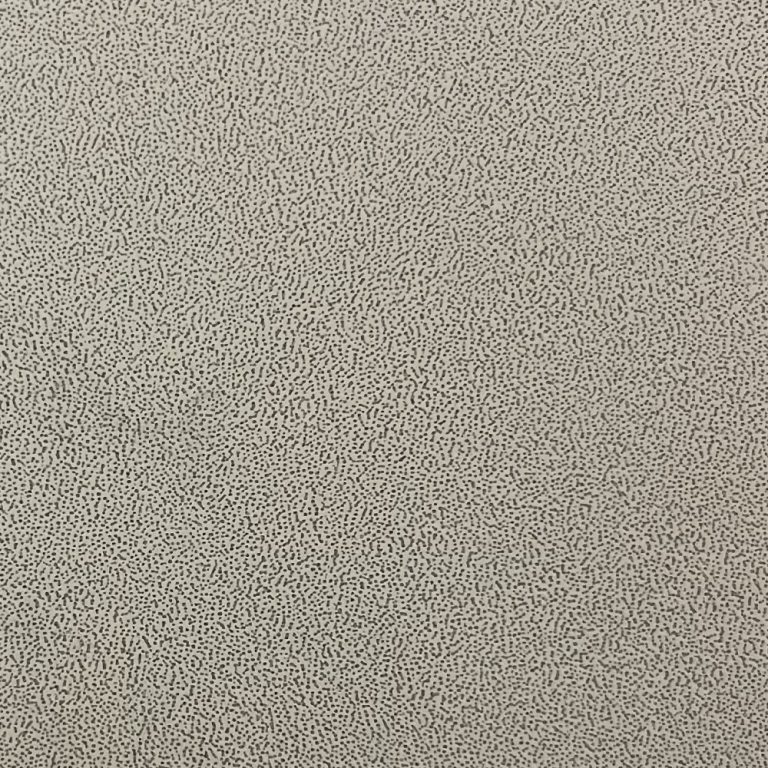

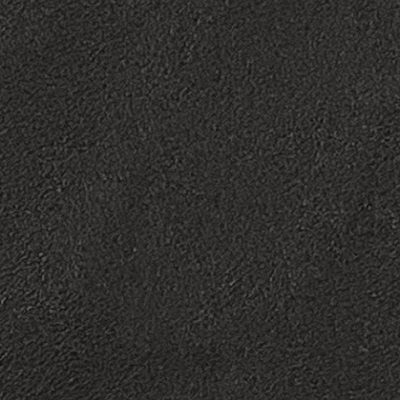

| Product Name | PU Base Leather |

| Nr. | 1 |

On the other hand, there are some drawbacks to using PU as a base material in production. One of the main concerns is its environmental impact. PU is a synthetic material that is derived from petrochemicals, which are non-renewable resources. The production of PU also generates emissions that contribute to air pollution and climate change. As a result, there is growing pressure on manufacturers to find more sustainable alternatives to PU base material.

Another drawback of using PU is its potential health risks. Some studies have suggested that certain chemicals used in the production of PU, such as isocyanates, can be harmful to human health. Workers who are exposed to these chemicals during the manufacturing process may experience respiratory issues or skin irritation. To mitigate these risks, manufacturers must adhere to strict safety regulations and provide proper training and protective equipment to their employees.

Despite these drawbacks, the benefits of using PU as a base material in production often outweigh the disadvantages. Its durability, flexibility, and lightweight properties make it a valuable material for a wide range of applications. As a PU base material producer, it is important to weigh the pros and cons of using PU in production and make informed decisions that prioritize both performance and sustainability. By staying informed about the latest developments in PU technology and investing in research and development, manufacturers can continue to harness the potential of PU as a versatile and innovative material.