Table of Contents

Crafting Quality: A Behind-the-Scenes Look at Our Leather Manufacturing Process

Crafting Quality: A Behind-the-Scenes Look at Our Leather Manufacturing Process

In the world of footwear, quality is paramount. From the moment a customer slips on a pair of shoes, they can feel the difference between craftsmanship and mediocrity. At the heart of this distinction lies the materials used in production, with leather being one of the most prized and enduring choices. But what goes into the creation of this essential component? Join us on a journey behind the scenes of our leather manufacturing process to uncover the meticulous craftsmanship and attention to detail that sets our footwear apart.

| Product | Sort |

| Shoe Upper | S |

Our process begins with the selection of premium hides sourced from reputable suppliers. We prioritize quality and sustainability, ensuring that our leather comes from ethical sources that adhere to strict environmental standards. Once the hides arrive at our facility, they undergo a rigorous inspection process to identify any imperfections or irregularities. Only the finest hides make the cut, ensuring that our leather meets the highest standards of excellence.

Next, the selected hides are prepared for tanning, a crucial step that transforms raw animal hides into durable and supple leather. Tanning is a complex process that involves treating the hides with various chemicals and natural substances to prevent decay and improve the material’s strength and flexibility. Our skilled artisans use time-honored techniques passed down through generations to achieve the perfect balance of texture, color, and durability.

| Product Name | Application Scenarios |

| PU thermo leather | Notebook |

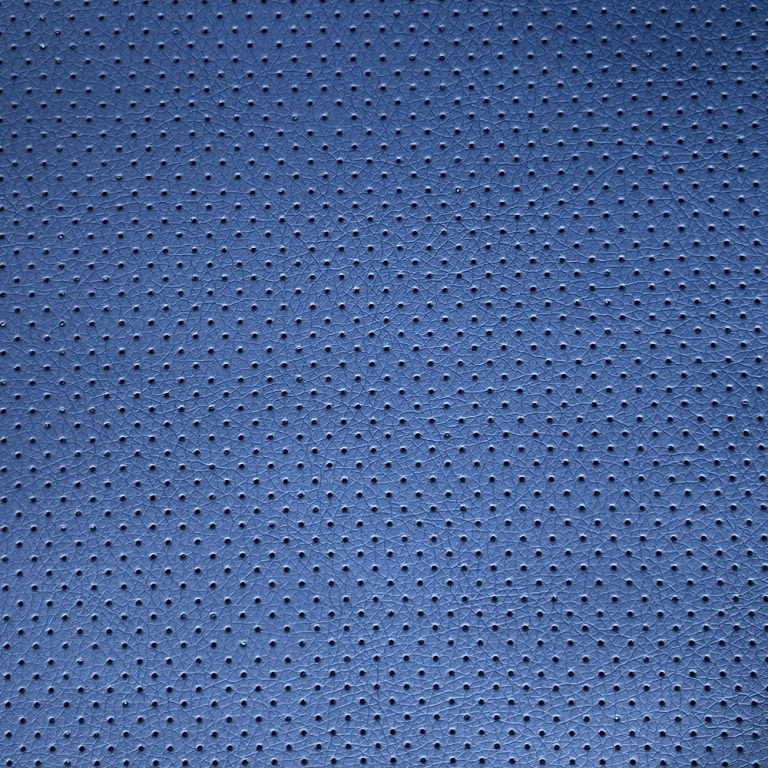

After tanning, the leather undergoes a series of finishing processes to enhance its appearance and performance. This includes trimming, buffing, and polishing the surface to achieve a smooth and uniform texture. Our artisans pay close attention to detail, meticulously inspecting each piece of leather to ensure that it meets our exacting standards for quality and consistency.

Once the leather has been finished, it is ready to be transformed into footwear components. Our craftsmen carefully cut and shape the leather according to precise patterns, taking care to minimize waste and maximize yield. Whether it’s a classic dress shoe or a rugged boot, every piece of leather is expertly crafted to fit seamlessly into the final product.

Throughout the manufacturing process, quality control is a top priority. Our dedicated team of inspectors conducts regular checks to verify the integrity of the leather and identify any defects or inconsistencies. From color matching to stitch tension, no detail is too small to escape their scrutiny. This relentless commitment to quality ensures that every pair of shoes that bears our name meets the highest standards of excellence.

In addition to quality, sustainability is also a core value of our manufacturing process. We are committed to minimizing our environmental footprint by reducing waste, conserving resources, and implementing eco-friendly practices wherever possible. From water recycling systems to energy-efficient machinery, we continually strive to minimize our impact on the planet while producing superior leather products.

In conclusion, the art of leather manufacturing is a testament to the marriage of tradition and innovation. From the careful selection of raw materials to the meticulous craftsmanship of skilled artisans, every step of the process is infused with a dedication to quality and excellence. By choosing our footwear, customers not only invest in a superior product but also support a legacy of craftsmanship that spans generations.

Sustainability in Footwear: How Our Leather Manufacturing Practices Are Redefining Eco-Friendly Fashion

In the realm of fashion, sustainability has become an increasingly important concern. As consumers become more conscious of their environmental impact, industries are compelled to reevaluate their practices to align with eco-friendly standards. In the footwear industry, where leather remains a popular material, manufacturers are under pressure to adopt more sustainable methods of production. One such trend is the emergence of eco-friendly leather manufacturing practices, aimed at reducing the environmental footprint of the footwear industry.

Traditional leather production has long been criticized for its environmental impact. The process involves various chemical treatments and consumes significant amounts of water and energy. Additionally, the livestock industry, which provides the raw materials for leather, is associated with deforestation, greenhouse gas emissions, and animal welfare concerns. Recognizing these issues, footwear leather manufacturers are actively seeking alternatives that prioritize sustainability without compromising on quality.

One approach gaining traction is the use of vegetable-tanned leather. Unlike conventional tanning methods that rely on toxic chemicals such as chromium, vegetable tanning utilizes natural substances like tree bark and plant extracts. This not only reduces the release of harmful pollutants into the environment but also results in a biodegradable end product. Furthermore, vegetable tanning is known for its ability to produce leather with unique textures and rich colors, appealing to both consumers and designers.

In addition to adopting more eco-friendly tanning methods, footwear leather manufacturers are exploring innovative ways to minimize waste throughout the production process. By implementing efficient cutting techniques and utilizing every part of the hide, manufacturers can reduce the amount of leather discarded as scrap. Moreover, some companies are investing in technologies that enable them to recycle and repurpose leather waste, further reducing their environmental impact.

Beyond production, sustainability also extends to the sourcing of raw materials. In response to growing concerns about deforestation and habitat destruction, many leather manufacturers are partnering with suppliers who adhere to responsible land management practices. By sourcing leather from certified sustainable sources, manufacturers can ensure that their products are not contributing to environmental degradation or the exploitation of vulnerable ecosystems.

Another key aspect of sustainable footwear manufacturing is transparency and traceability. Consumers are increasingly interested in knowing the origins of the products they purchase and the conditions under which they were made. In response, some footwear brands are implementing supply chain traceability systems that allow customers to trace the journey of their leather products from farm to factory. By providing this information, companies can build trust with consumers and demonstrate their commitment to ethical and sustainable practices.

Ultimately, the shift towards sustainability in footwear leather manufacturing represents a significant step forward for the fashion industry as a whole. By embracing eco-friendly practices, manufacturers can reduce their environmental impact, mitigate resource depletion, and contribute to the preservation of ecosystems. Moreover, as consumer demand for sustainable products continues to grow, companies that prioritize sustainability are likely to gain a competitive edge in the market.

In conclusion, sustainability is no longer just a buzzword in the fashion industry—it’s a necessity. In the realm of footwear leather manufacturing, this means rethinking traditional practices and embracing eco-friendly alternatives. From vegetable tanning to waste reduction initiatives, manufacturers are pioneering innovative solutions to minimize their environmental footprint. By prioritizing sustainability, the footwear industry can not only meet the demands of today’s conscious consumers but also pave the way for a more environmentally responsible future.