Maximizing Efficiency: Tips for Streamlining Production at Your Grip PU Factory

Maximizing Efficiency: Tips for Streamlining Production at Your Grip PU Factory

In the competitive landscape of manufacturing, efficiency is the key to success. As the owner or manager of a Grip PU factory, optimizing production processes is essential to remain competitive and meet customer demands. Fortunately, there are several strategies you can implement to streamline your operations and maximize efficiency.

First and foremost, investing in advanced technology and machinery can significantly enhance production efficiency. Modern equipment, such as computerized numerical control (CNC) machines and automated assembly lines, can perform tasks with greater precision and speed than traditional methods. By incorporating these technologies into your factory, you can minimize production time and reduce the risk of errors.

Additionally, optimizing workflow layout and organization is crucial for maximizing efficiency in a Grip PU factory. Analyze your current production layout and identify any bottlenecks or inefficiencies. By reorganizing workstations, implementing lean manufacturing principles, and minimizing unnecessary movement of materials and personnel, you can streamline the production process and increase output.

Furthermore, implementing robust quality control measures is essential for ensuring that only high-quality products leave your factory. By conducting regular inspections, testing, and audits throughout the production process, you can identify and address any issues or defects promptly. This not only reduces the likelihood of costly rework but also enhances customer satisfaction and loyalty.

Moreover, fostering a culture of continuous improvement among your workforce is vital for long-term success. Encourage employees to identify areas for optimization and empower them to implement solutions. By harnessing the collective knowledge and creativity of your team, you can drive innovation and efficiency throughout your Grip PU factory.

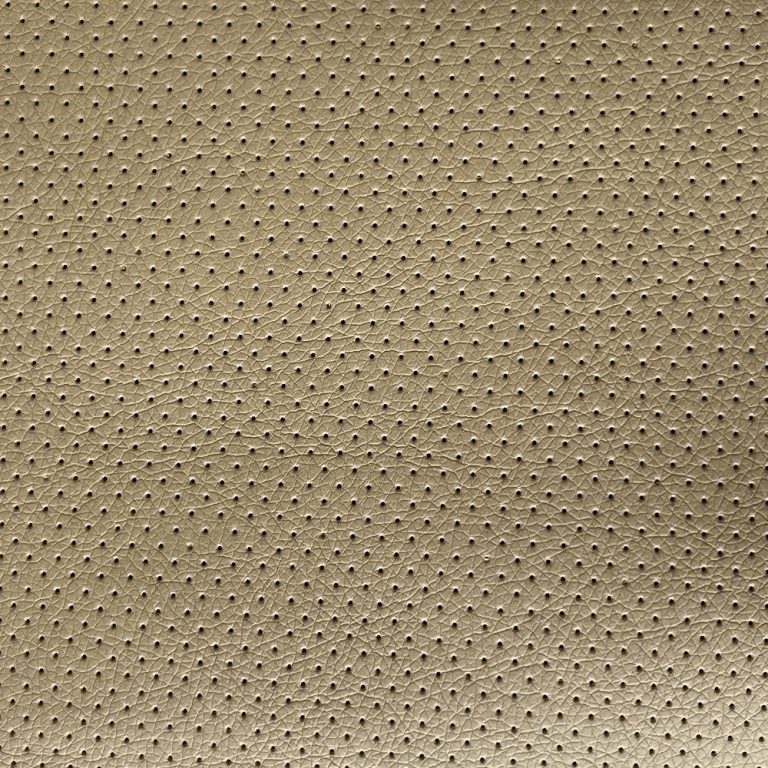

| Name | Variety |

| PU foam grip material | S |

Another effective strategy for maximizing efficiency is to establish strong partnerships with suppliers and distributors. By collaborating closely with trusted partners, you can ensure a steady supply of high-quality materials and components, as well as timely delivery of finished products to customers. This helps minimize downtime and maximize productivity within your factory.

Additionally, leveraging data analytics and technology can provide valuable insights into your production processes and performance. By collecting and analyzing data on key metrics such as production output, downtime, and defect rates, you can identify trends, patterns, and areas for improvement. This enables you to make data-driven decisions and optimize your operations for maximum efficiency.

Furthermore, implementing sustainable practices in your Grip PU factory can also contribute to efficiency gains. By reducing waste, energy consumption, and environmental impact, you can lower operating costs and enhance your reputation as a responsible manufacturer. Consider investing in energy-efficient equipment, recycling programs, and renewable energy sources to minimize your factory’s carbon footprint.

In conclusion, maximizing efficiency in a Grip PU factory requires a comprehensive approach that encompasses technology, workflow optimization, quality control, continuous improvement, collaboration, data analytics, and sustainability. By implementing these strategies, you can streamline your operations, increase productivity, and maintain a competitive edge in the market.