Table of Contents

Sustainable Practices in Shoe PU Manufacturing

Shoe PU manufacturing is a process that involves the use of polyurethane (PU) material to create durable and versatile footwear. However, the production of PU can have negative environmental impacts if not done responsibly. In recent years, there has been a growing emphasis on sustainable practices in the shoe manufacturing industry, including the use of eco-friendly materials and processes to reduce the carbon footprint of production.

One of the key aspects of sustainable shoe PU manufacturing is the use of recycled materials. Many manufacturers are now incorporating recycled PU into their shoe production process, reducing the need for virgin materials and minimizing waste. By using recycled materials, manufacturers can help reduce the environmental impact of shoe production and contribute to a more circular economy.

In addition to using recycled materials, sustainable shoe PU manufacturers are also focusing on reducing their energy consumption and carbon emissions. This can be achieved through the use of energy-efficient machinery and production processes, as well as the implementation of renewable energy sources such as solar or wind power. By reducing energy consumption and carbon emissions, manufacturers can lower their environmental impact and contribute to a more sustainable future.

Another important aspect of sustainable shoe PU manufacturing is the use of non-toxic and eco-friendly chemicals in the production process. Many traditional shoe manufacturing processes involve the use of harmful chemicals that can be harmful to both the environment and human health. By using non-toxic and eco-friendly chemicals, manufacturers can reduce their environmental impact and create safer products for consumers.

Furthermore, sustainable shoe PU manufacturers are also focusing on reducing water usage in the production process. Water is a precious resource that is often wasted in traditional manufacturing processes. By implementing water-saving technologies and practices, manufacturers can reduce their water usage and minimize their impact on the environment.

Overall, sustainable shoe PU manufacturing is an important aspect of the footwear industry that is gaining momentum. By incorporating recycled materials, reducing energy consumption and carbon emissions, using non-toxic chemicals, and minimizing water usage, manufacturers can create more environmentally friendly products that are better for the planet and for consumers. As consumers become more conscious of the environmental impact of their purchases, sustainable shoe PU manufacturing will continue to play a crucial role in the industry.

Latest Trends in Shoe PU Materials

Shoe manufacturers are constantly looking for new materials to enhance the quality and performance of their products. One material that has gained popularity in recent years is polyurethane (PU). PU is a versatile material that offers a wide range of benefits for shoe manufacturers, including durability, flexibility, and water resistance.

One of the latest trends in shoe PU materials is the use of eco-friendly and sustainable options. With increasing awareness of environmental issues, many consumers are looking for products that are made with sustainable materials. Shoe manufacturers are responding to this demand by using PU materials that are derived from renewable sources, such as plant-based oils or recycled plastics. These eco-friendly PU materials offer the same performance benefits as traditional PU, while also reducing the environmental impact of shoe production.

| Amount | Commodity Name |

| 1 | Shoe Upper |

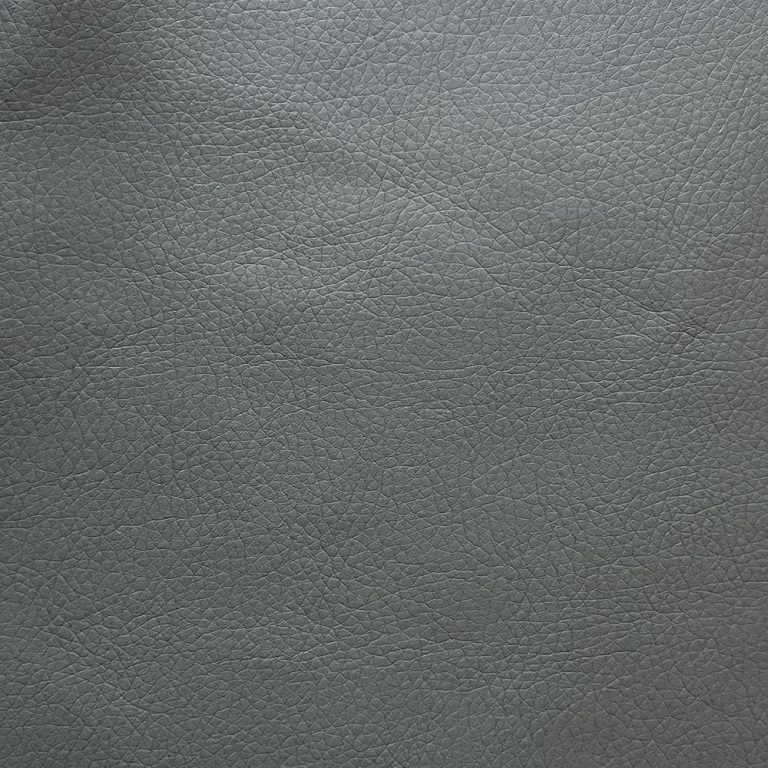

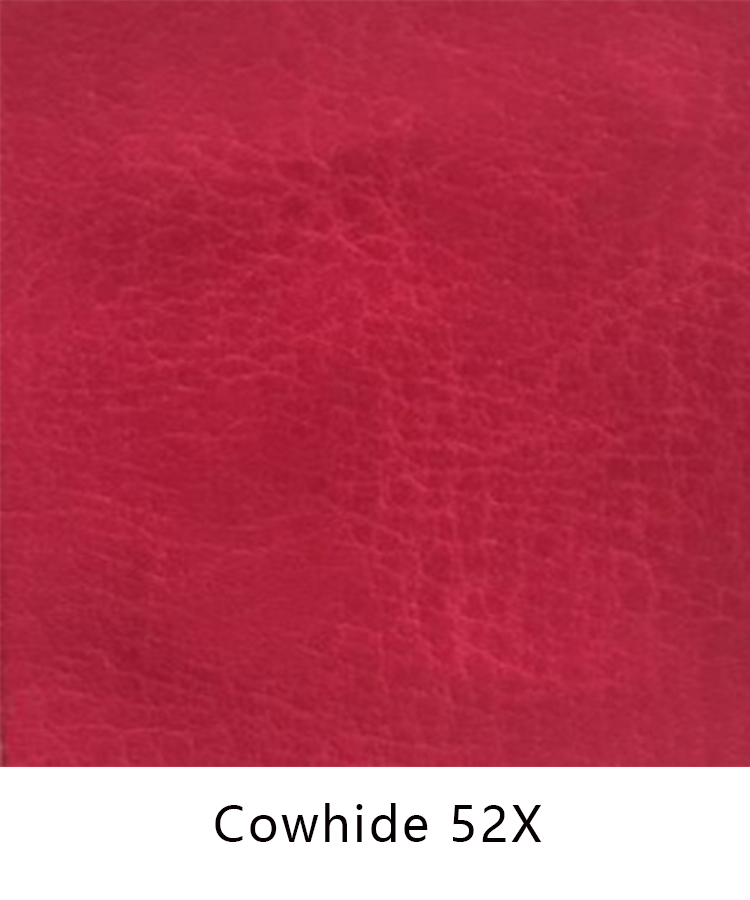

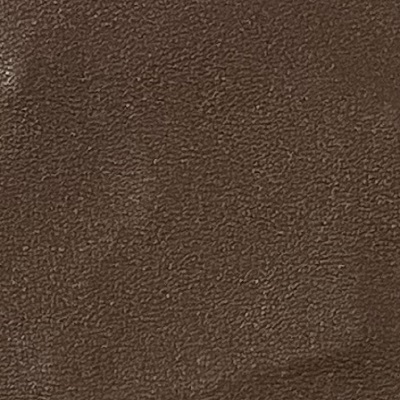

Another trend in shoe PU materials is the development of innovative finishes and textures. PU can be easily manipulated to create a variety of finishes, from smooth and glossy to textured and matte. Shoe manufacturers are experimenting with different finishes to create unique and eye-catching designs that set their products apart from the competition. Whether it’s a metallic sheen, a snakeskin texture, or a holographic finish, PU allows for endless possibilities in shoe design.

In addition to eco-friendly options and innovative finishes, shoe manufacturers are also focusing on improving the performance of PU materials. One area of development is in the area of breathability. PU is naturally water-resistant, which can be a double-edged sword when it comes to shoe comfort. While it keeps water out, it can also trap moisture inside the shoe, leading to discomfort and odor. To address this issue, shoe manufacturers are developing PU materials that are more breathable, allowing for better air circulation and moisture wicking.

Furthermore, shoe manufacturers are also looking to enhance the sustainability of PU materials by improving their recyclability. Traditional PU materials are difficult to recycle due to their complex chemical composition. However, researchers are working on developing new methods for recycling PU, such as chemical recycling or mechanical recycling. By making PU materials more recyclable, shoe manufacturers can reduce their environmental impact and create a more sustainable product.

Overall, the latest trends in shoe PU materials are focused on sustainability, innovation, and performance. By using eco-friendly materials, experimenting with new finishes, and improving breathability and recyclability, shoe manufacturers are able to create high-quality products that meet the demands of today’s consumers. As technology continues to advance, we can expect to see even more exciting developments in the world of shoe PU materials. Whether it’s a sleek and sustainable sneaker or a high-performance hiking boot, PU materials are sure to play a key role in the future of footwear design.

How Shoe PU Manufacturers are Embracing Technology

Shoe PU manufacturers have long been at the forefront of innovation in the footwear industry. With the rise of technology, these manufacturers are finding new ways to improve their processes and create high-quality products for consumers. From 3D printing to virtual reality, shoe PU manufacturers are embracing technology in a variety of ways to stay ahead of the competition.

One of the most significant advancements in shoe PU manufacturing is the use of 3D printing. This technology allows manufacturers to create prototypes and samples quickly and efficiently, reducing the time and cost associated with traditional manufacturing methods. By using 3D printing, manufacturers can also create custom designs and sizes for customers, providing a more personalized experience.

In addition to 3D printing, shoe PU manufacturers are also utilizing virtual reality to improve their design and production processes. Virtual reality allows designers to create and test new shoe designs in a virtual environment, reducing the need for physical prototypes and speeding up the production timeline. This technology also enables manufacturers to collaborate with designers and engineers from around the world, leading to more innovative and creative shoe designs.

Another way shoe PU manufacturers are embracing technology is through the use of automation and robotics in their production facilities. By automating certain tasks, manufacturers can increase efficiency, reduce errors, and improve overall product quality. Robotics can also help manufacturers handle complex tasks that are difficult or dangerous for human workers, leading to a safer and more productive work environment.

Furthermore, shoe PU manufacturers are incorporating smart technology into their products to enhance the consumer experience. Smart shoes can track a variety of metrics, such as steps taken, distance traveled, and calories burned, providing valuable data to consumers looking to improve their fitness and health. These shoes can also be connected to smartphones and other devices, allowing for seamless integration into everyday life.

Overall, the use of technology in shoe PU manufacturing is revolutionizing the industry and leading to more innovative and high-quality products for consumers. By embracing 3D printing, virtual reality, automation, robotics, and smart technology, manufacturers are able to create shoes that are not only stylish and comfortable but also durable and functional. As technology continues to advance, we can expect to see even more exciting developments in the world of shoe PU manufacturing.