Table of Contents

Production Process at a Sofa PU Factory

A sofa PU factory is a manufacturing facility that specializes in producing sofas made with polyurethane (PU) foam. The production process at a sofa PU factory involves several steps to ensure the quality and durability of the final product.

The first step in the production process at a sofa PU factory is the selection of raw materials. High-quality PU foam is essential for creating comfortable and long-lasting sofas. The factory must carefully source and inspect the raw materials to ensure they meet the necessary standards.

Once the raw materials have been selected, the next step is the cutting and shaping of the foam. This process involves cutting the foam into the desired shapes and sizes for the sofa cushions. Precision is key in this step to ensure that the cushions fit perfectly within the sofa frame.

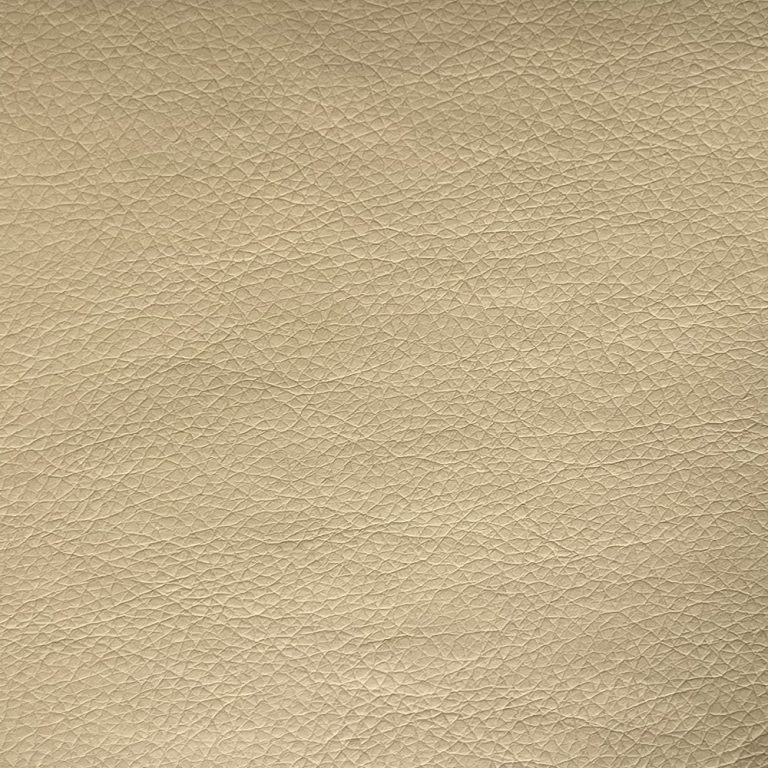

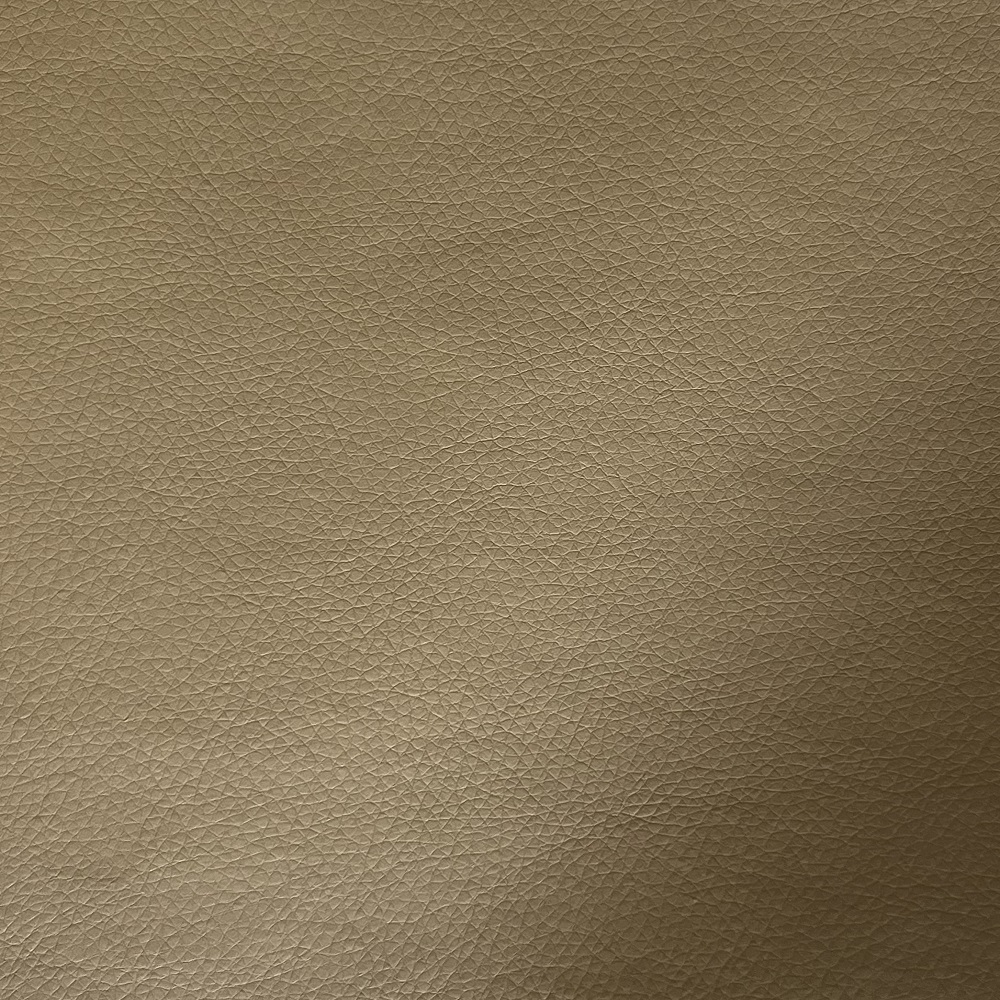

After the foam has been cut and shaped, it is then upholstered with fabric. The fabric is carefully chosen to complement the design of the sofa and provide a comfortable and aesthetically pleasing finish. Skilled workers use specialized equipment to upholster the foam cushions with the fabric, ensuring a tight and secure fit.

Once the cushions have been upholstered, they are then assembled into the sofa frame. The frame is typically made of wood or metal and provides the structure and support for the sofa. The cushions are carefully placed within the frame, and any final adjustments are made to ensure a perfect fit.

After the cushions have been assembled into the frame, the final step in the production process is the finishing touches. This may include adding decorative elements such as buttons or piping, as well as any additional features such as reclining mechanisms or built-in storage compartments. The sofa is then inspected for quality control to ensure that it meets the factory’s standards.

Throughout the production process at a sofa PU factory, quality control is a top priority. Inspections are conducted at each step to ensure that the sofas meet the necessary standards for comfort, durability, and aesthetics. Any defects or imperfections are addressed promptly to ensure that only high-quality products are shipped to customers.

In addition to quality control, efficiency is also important in the production process at a sofa PU factory. Streamlining operations and optimizing workflows help to reduce waste and increase productivity. This allows the factory to produce sofas more quickly and cost-effectively, ultimately benefiting both the factory and its customers.

Overall, the production process at a sofa PU factory is a complex and intricate operation that requires careful attention to detail and skilled craftsmanship. From selecting raw materials to adding the finishing touches, each step plays a crucial role in creating high-quality sofas that are comfortable, durable, and visually appealing. By following a systematic approach and prioritizing quality control and efficiency, a sofa PU factory can produce sofas that meet the needs and expectations of customers.

Benefits of Using PU Material in Sofa Manufacturing

When it comes to manufacturing sofas, choosing the right material is crucial to ensure durability, comfort, and aesthetics. One popular material that is widely used in sofa manufacturing is PU, or polyurethane. PU material offers a range of benefits that make it a preferred choice for many furniture manufacturers.

One of the key benefits of using PU material in sofa manufacturing is its durability. PU is a synthetic material that is designed to withstand wear and tear, making it ideal for furniture that is used frequently. Sofas made from PU material are less likely to show signs of wear such as cracking, peeling, or fading, ensuring that they maintain their appearance for years to come.

In addition to its durability, PU material is also easy to clean and maintain. Unlike natural materials such as leather or fabric, PU material is resistant to stains and spills, making it a practical choice for households with children or pets. Simply wiping down a PU sofa with a damp cloth is usually all that is needed to keep it looking clean and fresh.

Another benefit of using PU material in sofa manufacturing is its versatility. PU material can be easily molded into different shapes and designs, allowing for a wide range of styles and configurations. Whether you prefer a sleek modern sofa or a classic tufted design, PU material can be customized to suit your preferences.

Furthermore, PU material is available in a variety of colors and finishes, making it easy to find a sofa that complements your existing decor. Whether you prefer a bold statement piece or a subtle neutral tone, there is a PU sofa option to suit every taste.

In addition to its durability, ease of maintenance, and versatility, PU material is also a more affordable option compared to natural materials such as leather. This makes PU sofas a cost-effective choice for consumers who are looking to furnish their homes on a budget without compromising on quality.

Furthermore, PU material is also environmentally friendly. Unlike some natural materials that require the use of harsh chemicals in the manufacturing process, PU material can be produced using more sustainable methods. This makes PU sofas a more eco-friendly choice for consumers who are conscious of their environmental impact.

In conclusion, the benefits of using PU material in sofa manufacturing are clear. From its durability and ease of maintenance to its versatility and affordability, PU material offers a range of advantages that make it a popular choice for furniture manufacturers and consumers alike. Whether you are looking for a stylish and practical sofa for your living room or a comfortable and durable option for your family room, a PU sofa is a smart choice that ticks all the boxes.

Sustainability Practices in Sofa PU Factories

Sustainability Practices in Sofa PU Factories

In recent years, there has been a growing awareness of the environmental impact of the furniture industry. As consumers become more conscious of the need to reduce their carbon footprint, furniture manufacturers are also taking steps to implement sustainable practices in their production processes. One area where sustainability practices are particularly important is in sofa PU factories.

Polyurethane (PU) is a common material used in the production of sofas and other furniture. While PU is known for its durability and comfort, the production process can have a significant environmental impact. From the extraction of raw materials to the disposal of waste, every step in the production process can contribute to pollution and resource depletion.

To address these challenges, many sofa PU factories are implementing sustainability practices to reduce their environmental footprint. One key area of focus is the use of recycled materials in the production process. By using recycled PU foam and other materials, factories can reduce the demand for new raw materials and minimize waste. This not only helps to conserve natural resources but also reduces the amount of waste that ends up in landfills.

Another important sustainability practice in sofa PU factories is the use of energy-efficient technologies. By investing in energy-efficient equipment and processes, factories can reduce their energy consumption and lower their carbon emissions. This not only helps to protect the environment but also reduces operating costs for the factory, making it a win-win for both the business and the planet.

In addition to using recycled materials and energy-efficient technologies, many sofa PU factories are also implementing waste management practices to minimize their environmental impact. By recycling and reusing waste materials, factories can reduce the amount of waste that ends up in landfills and minimize their overall environmental footprint. This can include recycling scrap foam, fabric, and other materials, as well as implementing composting programs for organic waste.

Furthermore, some sofa PU factories are also exploring alternative materials and production processes to further reduce their environmental impact. This can include using plant-based foams, natural fibers, and other sustainable materials in place of traditional PU foam. By exploring these alternatives, factories can reduce their reliance on fossil fuels and minimize their carbon footprint.

| Amount | Commodity Name |

| 1 | PU upholstery fabrics for sofas and furniture |

Overall, sustainability practices in sofa PU factories are essential for reducing the environmental impact of the furniture industry. By using recycled materials, energy-efficient technologies, waste management practices, and alternative materials, factories can minimize their carbon footprint and protect the planet for future generations. As consumers continue to demand more sustainable products, it is crucial for sofa PU factories to prioritize sustainability in their production processes. By doing so, they can not only reduce their environmental impact but also attract environmentally conscious consumers who are looking for eco-friendly furniture options.