Table of Contents

Benefits of Using Base PU Material in Manufacturing

Polyurethane (PU) is a versatile material that is widely used in various industries for manufacturing a wide range of products. One of the key components of PU is the base material, which plays a crucial role in determining the properties and performance of the final product. In this article, we will explore the benefits of using base PU material in manufacturing and why it is preferred by many manufacturers.

One of the main advantages of using base PU material in manufacturing is its durability. PU is known for its high resistance to wear and tear, making it an ideal choice for products that are subjected to heavy use or harsh conditions. This durability ensures that products made from base PU material have a longer lifespan, reducing the need for frequent replacements and saving costs in the long run.

Another benefit of using base PU material is its flexibility. PU is a highly flexible material that can be molded into various shapes and sizes, making it suitable for a wide range of applications. This flexibility allows manufacturers to create products that are tailored to specific requirements, ensuring a perfect fit and optimal performance.

In addition to durability and flexibility, base PU material also offers excellent cushioning properties. PU is known for its ability to absorb shock and impact, making it an ideal choice for products that require cushioning or padding. This is particularly important in industries such as automotive and furniture, where comfort and safety are paramount.

| No. | Article Name |

| 1 | Water Based PU |

Furthermore, base PU material is lightweight, which makes it easy to handle and transport. This is especially beneficial for manufacturers who need to produce large quantities of products or ship them to different locations. The lightweight nature of PU helps to reduce shipping costs and makes handling and installation easier for end-users.

Moreover, base PU material is resistant to chemicals and oils, making it suitable for use in environments where exposure to these substances is common. This resistance ensures that products made from base PU material remain in good condition even in challenging conditions, prolonging their lifespan and maintaining their performance.

Additionally, base PU material is easy to maintain and clean, making it a practical choice for products that require regular upkeep. This ease of maintenance helps to prolong the lifespan of products and ensures that they continue to perform optimally over time.

In conclusion, base PU material offers a wide range of benefits for manufacturers looking to produce high-quality, durable products. From its durability and flexibility to its cushioning properties and resistance to chemicals, base PU material is a versatile option that can be used in a variety of applications. By choosing base PU material for manufacturing, manufacturers can create products that are not only long-lasting and reliable but also cost-effective and easy to maintain.

How to Choose the Right Base PU Material Supplier for Your Business

When it comes to choosing the right base PU material supplier for your business, there are several factors to consider. The quality of the materials you use in your products can have a significant impact on the overall success of your business. Therefore, it is crucial to find a reliable and reputable supplier that can provide you with high-quality base PU materials that meet your specific needs.

One of the first things to consider when choosing a base PU material supplier is the quality of their products. It is essential to work with a supplier that offers materials that are of consistent quality and meet industry standards. This will ensure that your products are of high quality and will help you maintain a good reputation with your customers.

Another important factor to consider is the supplier’s reliability and reputation. You want to work with a supplier that you can trust to deliver materials on time and in the quantities you need. A supplier with a good reputation in the industry is more likely to provide you with excellent customer service and support, which can be invaluable when it comes to running your business smoothly.

Cost is also a significant consideration when choosing a base PU material supplier. While it is essential to find a supplier that offers competitive pricing, it is equally important to consider the overall value that the supplier provides. This includes factors such as the quality of their products, their reliability, and their customer service. It is essential to strike a balance between cost and quality to ensure that you are getting the best value for your money.

When evaluating potential base PU material suppliers, it is also important to consider their production capacity and capabilities. You want to work with a supplier that can meet your production needs and scale with your business as it grows. This may involve visiting the supplier’s facilities and assessing their equipment, processes, and workforce to ensure that they can handle your requirements.

Communication is another critical factor to consider when choosing a base PU material supplier. You want to work with a supplier that is responsive to your inquiries and can provide you with timely updates on your orders. Good communication is essential for building a strong relationship with your supplier and ensuring that your needs are met.

| Product Name | PU Base Material |

| Nr. | 1 |

Finally, it is essential to consider the supplier’s environmental and ethical practices. As consumers become more conscious of sustainability and ethical sourcing, it is crucial for businesses to align themselves with suppliers that share these values. Choosing a supplier that prioritizes environmental sustainability and ethical practices can help you attract environmentally conscious customers and enhance your brand reputation.

In conclusion, choosing the right base PU material supplier for your business is a crucial decision that can have a significant impact on your success. By considering factors such as quality, reliability, cost, production capacity, communication, and environmental and ethical practices, you can find a supplier that meets your specific needs and helps you achieve your business goals. Take the time to research potential suppliers, ask for references, and visit their facilities to ensure that you are making an informed decision. By choosing the right supplier, you can set your business up for long-term success and growth.

Top Trends in Base PU Material Supply Industry

The base PU material supply industry is constantly evolving, with new trends emerging each year. As technology advances and consumer preferences change, suppliers must stay ahead of the curve to meet the demands of their customers. In this article, we will explore some of the top trends in the base PU material supply industry and how they are shaping the future of the industry.

One of the biggest trends in the base PU material supply industry is the shift towards sustainable and eco-friendly materials. With increasing awareness of the environmental impact of traditional materials, many suppliers are now offering products that are made from recycled or renewable sources. This not only helps to reduce waste and carbon emissions but also appeals to environmentally conscious consumers who are looking for more sustainable options.

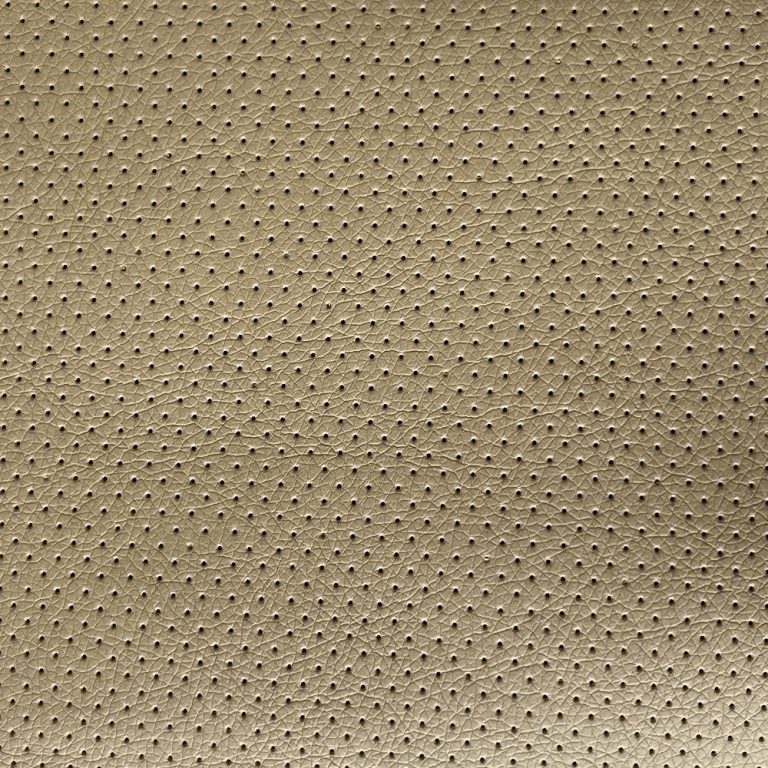

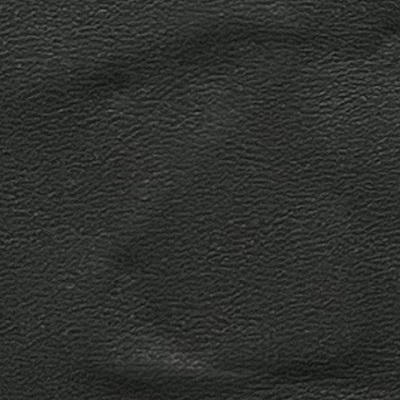

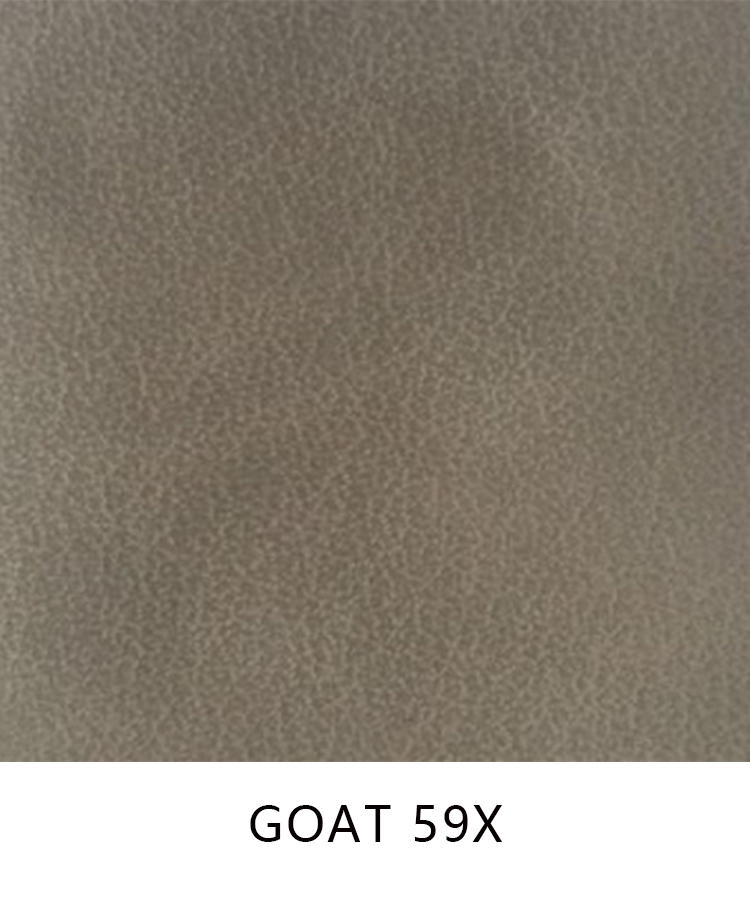

Another trend in the base PU material supply industry is the focus on customization and personalization. As consumers become more discerning and demanding, suppliers are offering a wider range of colors, textures, and finishes to cater to individual preferences. This trend is driven by the rise of customization in other industries, such as fashion and technology, and is expected to continue to grow in the coming years.

In addition to sustainability and customization, digitalization is also playing a key role in shaping the base PU material supply industry. With the rise of e-commerce and online shopping, suppliers are now able to reach a wider audience and offer their products to customers around the world. This has led to increased competition but also greater opportunities for growth and expansion.

Furthermore, automation and robotics are becoming increasingly important in the base PU material supply industry. By automating processes such as cutting, molding, and finishing, suppliers are able to increase efficiency, reduce costs, and improve quality control. This trend is expected to continue as technology continues to advance and become more affordable for smaller suppliers.

One of the most significant trends in the base PU material supply industry is the growing demand for high-performance materials. With consumers looking for products that are durable, lightweight, and versatile, suppliers are now focusing on developing materials that meet these requirements. This trend is driven by the increasing use of PU materials in a wide range of industries, from automotive and construction to fashion and furniture.

Overall, the base PU material supply industry is experiencing rapid change and evolution, driven by a combination of technological advancements, changing consumer preferences, and increasing competition. Suppliers who are able to adapt to these trends and innovate their products and processes will be well-positioned to succeed in this dynamic and fast-paced industry. By staying ahead of the curve and embracing new opportunities, base PU material suppliers can continue to thrive and grow in the years to come.