Streamlining Production Processes in Shoe Factories: Enhancing Efficiency and Quality

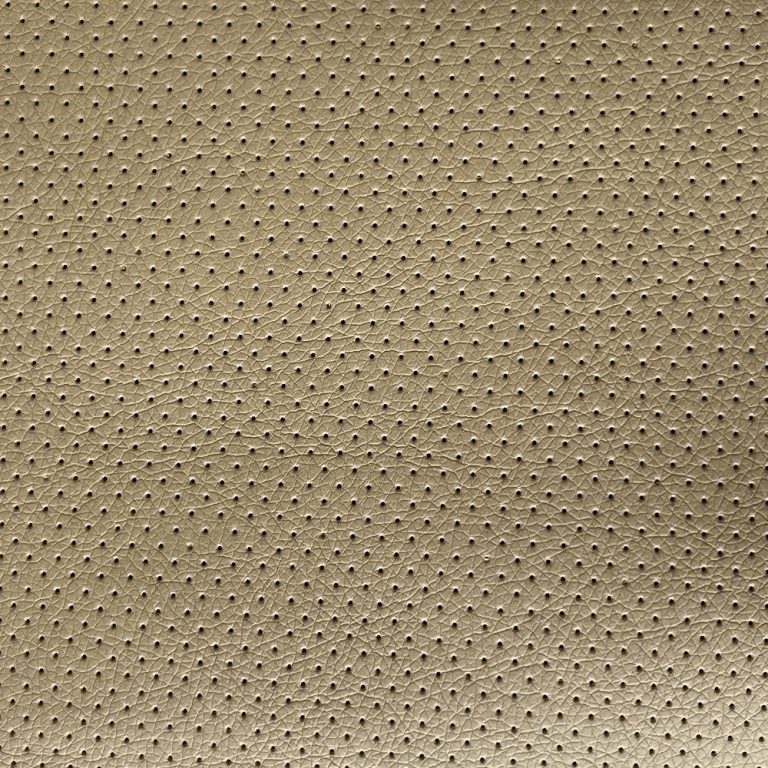

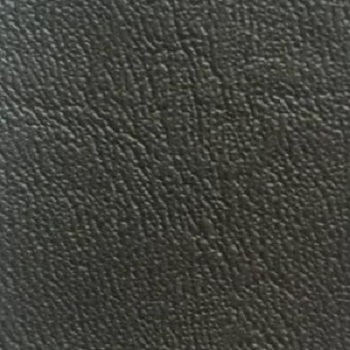

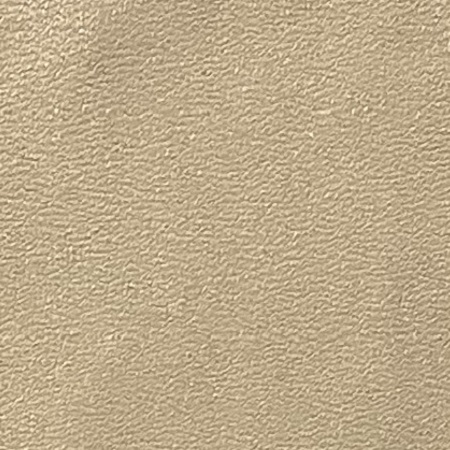

In the ever-evolving landscape of manufacturing, efficiency and quality are paramount. This is particularly true in industries like footwear, where consumer demand for both style and durability drives production processes. One key aspect of this industry is the manufacturing of shoe linings, a crucial component that impacts both the comfort and longevity of footwear.

Shoe lining factories play a pivotal role in the overall production process of shoes. These facilities are tasked with producing linings that provide comfort, support, and moisture-wicking properties to the wearer. However, like any manufacturing operation, lining shoe factories face challenges in optimizing their processes to meet the demands of the market.

One of the primary goals of streamlining production processes in shoe lining factories is to enhance efficiency. This involves identifying bottlenecks in the manufacturing process and implementing strategies to eliminate or minimize them. By streamlining workflows, factories can reduce lead times, optimize resource utilization, and ultimately increase output without compromising on quality.

| Product | Shoe inner lining |

| Nr. | 1 |

One approach to improving efficiency in lining shoe factories is through the adoption of lean manufacturing principles. This involves eliminating waste, standardizing processes, and continuously improving operations. By implementing practices such as just-in-time manufacturing and kanban systems, factories can reduce inventory costs and improve overall productivity.

Another key aspect of enhancing efficiency in lining shoe factories is the implementation of automation technologies. Automation can help streamline repetitive tasks, increase throughput, and improve consistency in product quality. From automated cutting and stitching machines to robotic material handling systems, technology plays a crucial role in modernizing production processes.

However, while efficiency is essential, it should not come at the expense of quality. Maintaining high standards of craftsmanship and product excellence is paramount in the footwear industry. Therefore, any efforts to streamline production processes must also focus on maintaining or even improving product quality.

One way to achieve this balance is through the implementation of quality control measures throughout the production process. By conducting thorough inspections at each stage of manufacturing, factories can identify and address any defects or deviations from specifications before they escalate into larger issues. This proactive approach not only helps ensure that each lining meets quality standards but also reduces the likelihood of costly rework or recalls.

Furthermore, investing in employee training and development is critical for maintaining quality standards in lining shoe factories. Well-trained staff are better equipped to operate machinery effectively, identify quality issues, and implement corrective actions when necessary. By fostering a culture of continuous learning and improvement, factories can empower their workforce to uphold the highest standards of quality in every aspect of production.

In conclusion, streamlining production processes in lining shoe factories is essential for enhancing efficiency and quality. By adopting lean manufacturing principles, leveraging automation technologies, and implementing robust quality control measures, factories can optimize their operations to meet the demands of the market while upholding the highest standards of craftsmanship. By striking the right balance between efficiency and quality, lining shoe factories can remain competitive in an increasingly dynamic industry landscape.