Table of Contents

The Importance of Quality Lining in Shoe Production: A Guide for Manufacturers

Quality lining in shoe production is an essential component that often goes unnoticed by consumers, yet plays a significant role in the comfort, durability, and overall quality of the footwear. For manufacturers, understanding the importance of quality lining and investing in its production is paramount to producing shoes that not only look good but also feel good to wear.

First and foremost, the lining of a shoe serves as a barrier between the foot and the outer material of the shoe. This layer is in direct contact with the wearer’s skin, making it crucial for providing comfort and preventing irritation or chafing. Low-quality linings can cause discomfort, leading to blisters, hot spots, and overall dissatisfaction with the shoe. Therefore, manufacturers must prioritize using materials that are soft, breathable, and gentle on the skin.

Moreover, quality lining enhances the structural integrity of the shoe by providing support and stability. A well-constructed lining helps the shoe maintain its shape over time, preventing it from sagging or deforming with wear. This is particularly important for certain types of footwear, such as boots or high heels, where the lining plays a critical role in keeping the foot securely in place and preventing slippage.

In addition to comfort and support, quality lining also contributes to the longevity of the shoe. Durable materials resist wear and tear, extending the lifespan of the footwear and reducing the need for frequent replacements. For manufacturers, this translates to cost savings and a more sustainable approach to production, as fewer shoes end up in landfills due to premature deterioration.

Transitional phrases help guide the reader through the article, smoothly transitioning from one idea to the next. For example, “Furthermore,” “In addition,” and “Moreover” help to connect related points, while “First and foremost” and “Therefore” signal shifts in focus or conclusions.

Furthermore, quality lining can also enhance the overall aesthetic appeal of the shoe. While the lining may not always be visible to the consumer, its presence is felt in the overall look and feel of the footwear. A well-made lining adds a layer of sophistication and refinement to the shoe, elevating its perceived value and desirability.

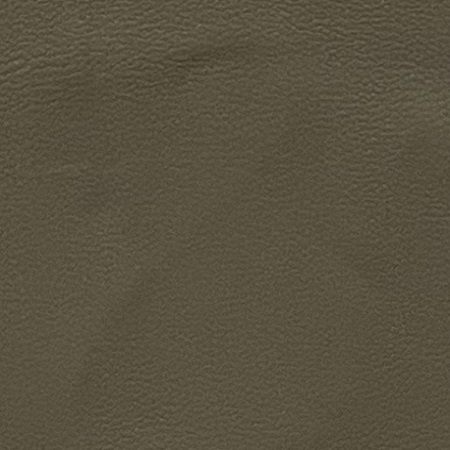

| Product | Use |

| Shoe inner lining | Shoes,Bags, Clothes |

In conclusion, quality lining is a crucial aspect of shoe production that should not be overlooked by manufacturers. Investing in materials and processes that prioritize comfort, support, durability, and aesthetics can lead to higher customer satisfaction, increased brand loyalty, and ultimately, greater success in the competitive footwear market. By understanding the importance of quality lining and incorporating it into their production practices, manufacturers can ensure that their shoes not only look good but also feel good to wear, delivering a superior experience for consumers.

Innovative Materials and Techniques for Superior Shoe Lining: Enhancing Comfort and Durability

In the realm of footwear manufacturing, every detail counts, from the outer design to the inner construction. One often-overlooked aspect crucial to both comfort and durability is the lining of shoes. While it may seem like a minor component, the lining plays a significant role in enhancing the overall quality of footwear. In recent years, the industry has witnessed a surge in innovative materials and techniques aimed at improving shoe linings, providing consumers with superior comfort and durability.

Traditionally, shoe linings were primarily made from natural materials such as leather and textile fabrics. While these materials offer certain benefits, such as breathability and flexibility, they also come with limitations in terms of durability and moisture-wicking properties. As consumer expectations evolve and demands for higher performance increase, footwear manufacturers have turned to cutting-edge materials and techniques to meet these requirements.

One of the most notable advancements in shoe lining production is the use of synthetic materials engineered specifically for footwear applications. Synthetic linings offer several advantages over traditional materials, including enhanced durability, moisture management, and breathability. Materials like microfiber and mesh fabrics are lightweight, flexible, and resistant to wear and tear, making them ideal choices for lining shoes intended for rigorous activities or long-term wear.

Moreover, advancements in manufacturing techniques, such as seamless construction and 3D printing, have revolutionized the way shoe linings are produced. Seamless construction eliminates the need for stitching, reducing the risk of irritation and friction points inside the shoe. This not only enhances comfort but also improves the overall aesthetics of the footwear. Additionally, 3D printing allows for precise customization of shoe linings, ensuring a perfect fit and optimal performance for each individual wearer.

Another area of innovation in shoe lining production is the integration of performance-enhancing technologies. Companies are incorporating features such as moisture-wicking treatments, antimicrobial agents, and cushioning systems directly into the lining materials. These technologies help manage moisture and odor, prevent bacterial growth, and provide extra support and comfort where needed, resulting in a more comfortable and hygienic wearing experience.

Furthermore, sustainability has become a key focus in the footwear industry, prompting manufacturers to explore eco-friendly alternatives for shoe linings. Recycled materials, such as PET bottles and reclaimed fibers, are being utilized to create linings that not only offer performance benefits but also reduce the environmental impact of footwear production. Additionally, bio-based materials derived from renewable sources are gaining traction as sustainable alternatives to traditional synthetic linings.

As consumer awareness grows regarding the environmental and ethical implications of their purchasing decisions, brands are increasingly investing in sustainable practices throughout their supply chains, including the sourcing and production of shoe linings. By prioritizing eco-friendly materials and manufacturing processes, companies can appeal to environmentally conscious consumers and contribute to the ongoing sustainability efforts within the footwear industry.

In conclusion, the evolution of materials and techniques used in shoe lining production has led to significant improvements in comfort, durability, and sustainability. From synthetic materials and seamless construction to performance-enhancing technologies and eco-friendly alternatives, footwear manufacturers are continuously striving to enhance the quality and performance of shoe linings. As a result, consumers can expect footwear that not only looks stylish but also feels comfortable, lasts longer, and aligns with their values regarding environmental responsibility.