Inhoudsopgave

Pros and Cons of PU Lining in Automotive Applications

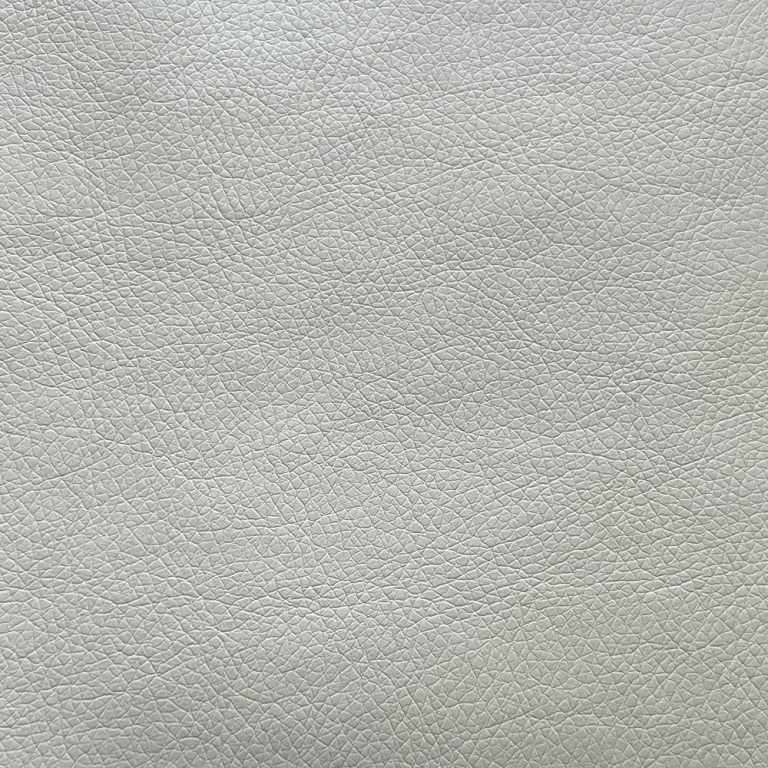

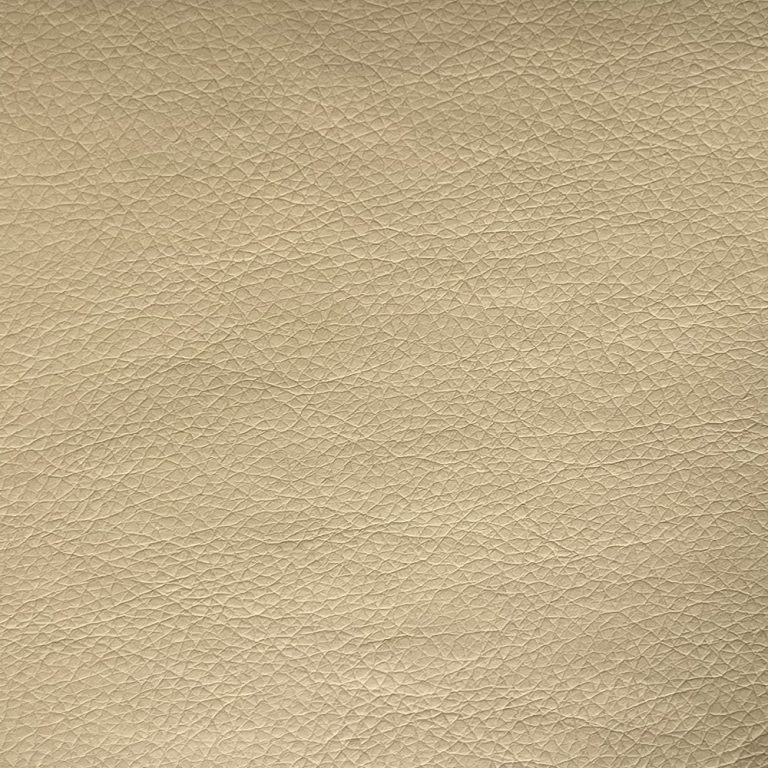

Polyurethane (PU) lining is a popular choice for automotive applications due to its durability, flexibility, and resistance to chemicals and abrasion. However, like any material, PU lining has its pros and cons that should be considered before choosing it for a specific application.

One of the main advantages of PU lining is its durability. PU is a tough material that can withstand heavy use and harsh conditions, making it ideal for automotive applications where the lining may be exposed to rough handling or extreme temperatures. This durability can help extend the lifespan of the lining and reduce the need for frequent replacements, saving time and money in the long run.

In addition to its durability, PU lining is also flexible, allowing it to conform to the shape of the surface it is applied to. This flexibility makes PU lining easy to install and can help ensure a tight, secure fit that provides maximum protection. It also allows for some movement without cracking or breaking, which can be important in automotive applications where parts may shift or vibrate during use.

Another benefit of PU lining is its resistance to chemicals and abrasion. PU is highly resistant to a wide range of chemicals, including oils, fuels, and solvents, making it a good choice for applications where the lining may come into contact with these substances. Its resistance to abrasion also helps protect the underlying surface from wear and tear, extending its lifespan and reducing maintenance costs.

Despite its many advantages, PU lining also has some drawbacks that should be considered. One of the main disadvantages of PU lining is its cost. PU is typically more expensive than other lining materials, such as rubber or PVC, which can make it less cost-effective for some applications. However, the durability and longevity of PU lining may offset this initial cost over time.

Another potential downside of PU lining is its environmental impact. PU is a synthetic material that is derived from petrochemicals, which are non-renewable resources. The production of PU also generates greenhouse gas emissions, contributing to climate change. While efforts are being made to develop more sustainable alternatives to traditional PU, such as bio-based PU, these options may not yet be widely available or cost-effective.

In conclusion, PU lining offers many benefits for automotive applications, including durability, flexibility, and resistance to chemicals and abrasion. However, it also has some drawbacks, such as cost and environmental impact, that should be taken into consideration when choosing a lining material. Ultimately, the decision to use PU lining will depend on the specific requirements of the application and the priorities of the manufacturer or end user.

How to Properly Maintain and Care for PU Lining in Industrial Settings

Polyurethane (PU) lining is a popular choice for industrial settings due to its durability and resistance to chemicals, abrasion, and impact. However, like any other material, PU lining requires proper maintenance and care to ensure its longevity and effectiveness. In this article, we will discuss some tips on how to properly maintain and care for PU lining in industrial settings.

One of the most important aspects of maintaining PU lining is regular cleaning. It is essential to clean PU lining regularly to remove any dirt, debris, or chemicals that may have accumulated on its surface. This can be done using a mild detergent and water solution, along with a soft brush or cloth. Avoid using harsh chemicals or abrasive materials, as they can damage the PU lining and reduce its effectiveness.

In addition to regular cleaning, it is also important to inspect the PU lining for any signs of wear or damage. Check for any cracks, tears, or peeling, as these can compromise the integrity of the lining and lead to leaks or other issues. If any damage is found, it should be repaired or replaced as soon as possible to prevent further damage.

Another important aspect of maintaining PU lining is proper storage. When not in use, PU lining should be stored in a cool, dry place away from direct sunlight and extreme temperatures. This will help prevent the lining from degrading prematurely and ensure its longevity.

| Products | Shoe Upper |

| Amount | 1 |

In addition to regular cleaning and inspection, it is also important to avoid exposing PU lining to harsh chemicals or solvents. These can break down the lining and reduce its effectiveness, leading to leaks or other issues. If exposure to chemicals is unavoidable, be sure to clean the lining thoroughly afterwards to remove any residue.

Proper handling is also crucial when it comes to maintaining PU lining. Avoid dragging or dropping heavy objects on the lining, as this can cause damage. Instead, use proper lifting techniques and equipment to prevent unnecessary strain on the lining.

Regular maintenance is key to ensuring the longevity and effectiveness of PU lining in industrial settings. By following these tips and guidelines, you can help protect your investment and keep your PU lining in top condition for years to come.

In conclusion, PU lining is a durable and versatile material that is commonly used in industrial settings. Proper maintenance and care are essential to ensure the longevity and effectiveness of PU lining. By following the tips outlined in this article, you can help protect your investment and keep your PU lining in top condition. Remember to clean and inspect the lining regularly, store it properly, avoid exposure to harsh chemicals, and handle it with care. By taking these steps, you can help extend the life of your PU lining and ensure its continued performance in your industrial setting.

The Environmental Impact of PU Lining and Sustainable Alternatives

Polyurethane (PU) lining is a commonly used material in various industries for its durability and versatility. However, the environmental impact of PU lining has raised concerns among environmentalists and consumers alike. In this article, we will explore the environmental impact of PU lining and discuss sustainable alternatives that can help mitigate its negative effects.

PU lining is a synthetic material that is derived from petroleum-based chemicals. The production of PU lining involves the use of fossil fuels, which contributes to greenhouse gas emissions and air pollution. Additionally, the manufacturing process of PU lining generates hazardous waste that can harm the environment if not properly disposed of. These environmental impacts make PU lining a less sustainable choice compared to other lining materials.

One of the main concerns with PU lining is its non-biodegradability. Once PU lining reaches the end of its lifespan, it often ends up in landfills where it can take hundreds of years to decompose. This not only contributes to the growing problem of waste management but also poses a threat to wildlife and ecosystems. The accumulation of non-biodegradable materials like PU lining in landfills can lead to soil and water contamination, further exacerbating environmental issues.

In addition to its non-biodegradability, PU lining also has a high carbon footprint. The production of PU lining requires a significant amount of energy, which is primarily sourced from fossil fuels. This reliance on fossil fuels for energy contributes to the depletion of natural resources and the exacerbation of climate change. As the demand for PU lining continues to grow, so does its environmental impact, making it imperative to explore sustainable alternatives.

One sustainable alternative to PU lining is the use of natural materials such as cork, bamboo, or organic cotton. These materials are renewable, biodegradable, and have a lower environmental impact compared to PU lining. For example, cork is a sustainable material that is harvested from the bark of cork oak trees without harming the tree itself. Cork is not only biodegradable but also has natural antimicrobial properties, making it an ideal choice for lining materials.

Another sustainable alternative to PU lining is the use of recycled materials. Recycled plastics, rubber, or textiles can be repurposed into lining materials, reducing the demand for virgin materials and diverting waste from landfills. By incorporating recycled materials into lining products, manufacturers can help reduce their environmental impact and promote a circular economy.

Furthermore, advancements in technology have led to the development of bio-based polymers that can be used as alternatives to PU lining. These bio-based polymers are derived from renewable sources such as corn, sugarcane, or algae, making them more sustainable and environmentally friendly. By replacing traditional PU lining with bio-based polymers, manufacturers can reduce their carbon footprint and support the transition to a more sustainable future.

In conclusion, the environmental impact of PU lining is a growing concern that requires immediate attention. By exploring sustainable alternatives such as natural materials, recycled materials, and bio-based polymers, manufacturers can reduce their environmental footprint and promote a more sustainable approach to lining materials. It is essential for industries to prioritize sustainability and invest in eco-friendly solutions to mitigate the negative effects of PU lining on the environment.