Innovative Techniques in Shoe Lining: Elevating Comfort and Durability

Innovative Techniques in Shoe Lining: Elevating Comfort and Durability

The world of footwear design is constantly evolving, driven by a quest for enhanced comfort, performance, and durability. Among the crucial elements contributing to these factors is the shoe lining. Often overlooked by consumers, the lining plays a pivotal role in ensuring a comfortable fit, moisture management, and overall longevity of the shoe. In recent years, manufacturers have been pushing the boundaries of innovation in shoe lining techniques, employing advanced materials and construction methods to elevate both comfort and durability.

One of the key innovations in shoe lining technology lies in the use of moisture-wicking fabrics. Traditional shoe linings were often made from materials like leather or synthetic textiles, which could trap moisture and lead to discomfort, especially during prolonged wear. However, modern linings incorporate moisture-wicking properties, drawing sweat away from the foot and allowing it to evaporate, thus keeping the interior of the shoe dry and comfortable. This innovation not only enhances wearer comfort but also helps to prevent odors and prolong the lifespan of the shoe.

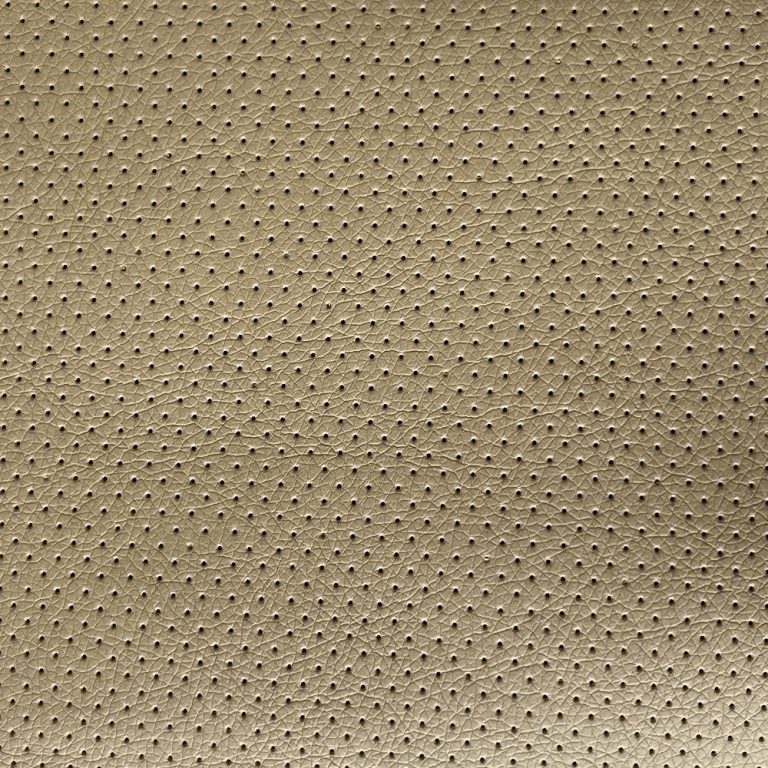

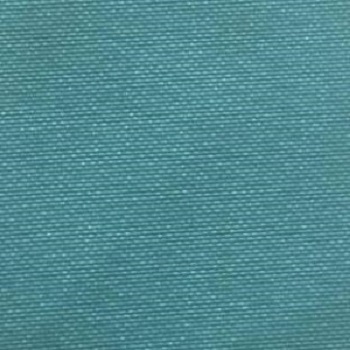

In addition to moisture-wicking properties, manufacturers are also focusing on enhancing the breathability of shoe linings. Breathable linings allow air to circulate freely within the shoe, helping to regulate temperature and reduce the risk of overheating or moisture buildup. This is particularly beneficial for athletic shoes and other footwear designed for active use, where foot perspiration is more likely to occur. By incorporating breathable materials such as mesh or perforated fabrics into the lining construction, manufacturers are able to strike a balance between comfort and performance, ensuring that wearers can stay cool and comfortable even during the most demanding activities.

Furthermore, advancements in shoe lining technology are not limited to materials alone but also extend to construction techniques. One notable innovation in this regard is the use of seamless lining construction. Traditional shoe linings often feature seams and stitching, which can create pressure points and lead to discomfort, especially in sensitive areas of the foot. By employing seamless construction methods, manufacturers are able to eliminate these potential sources of irritation, providing a smoother and more comfortable interior surface for the foot. This not only enhances wearer comfort but also contributes to the overall durability of the shoe, as seamless linings are less prone to wear and tear over time.

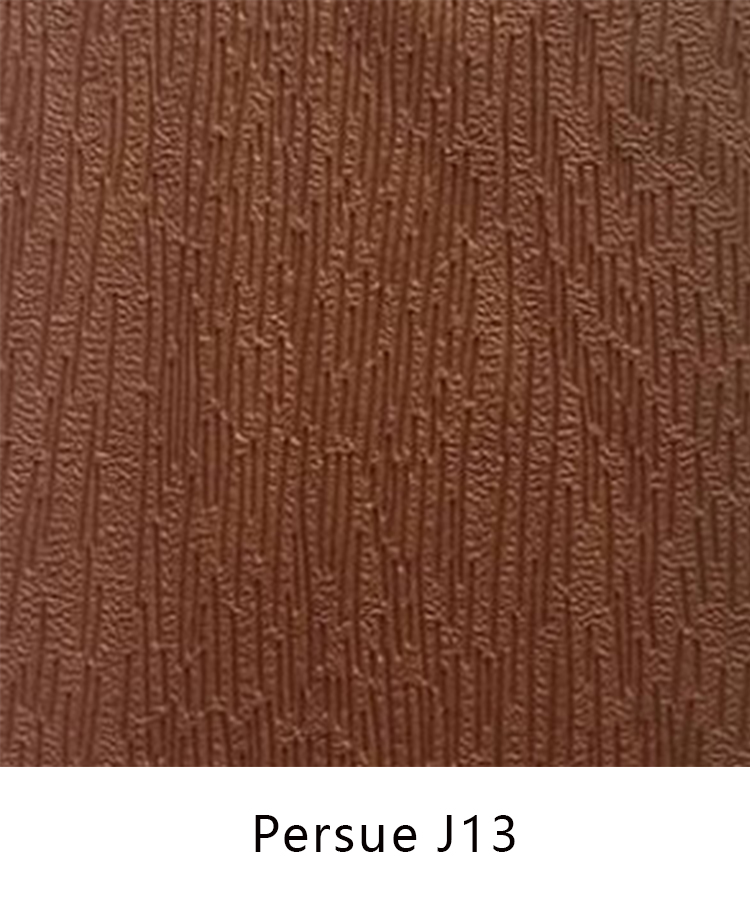

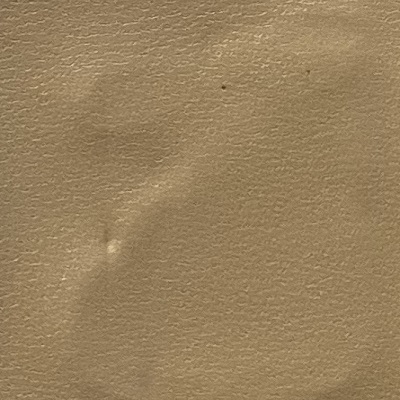

| Article Name | Use |

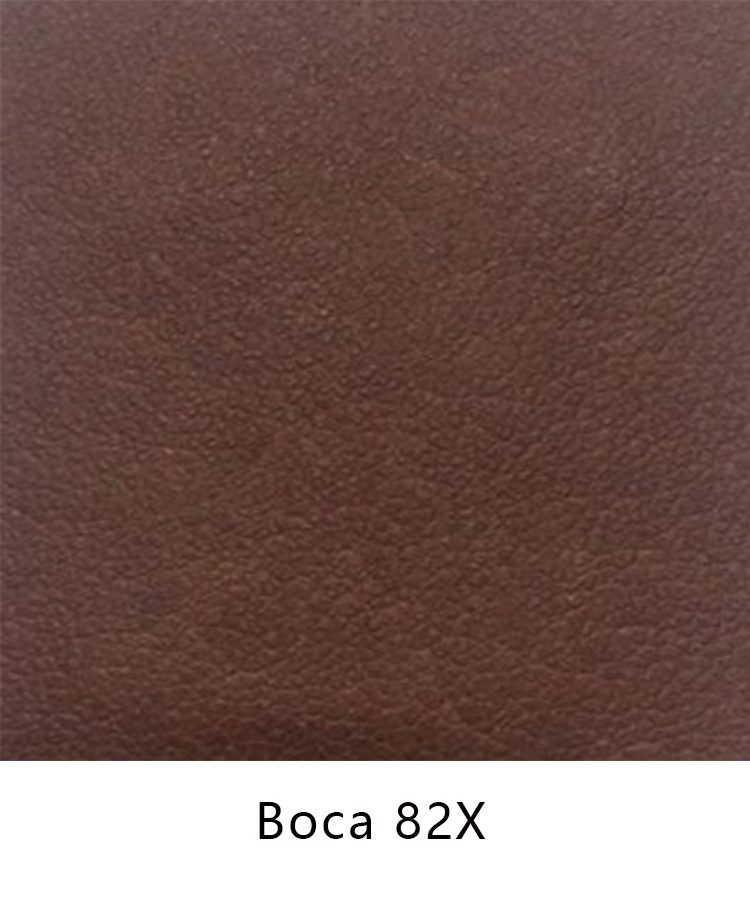

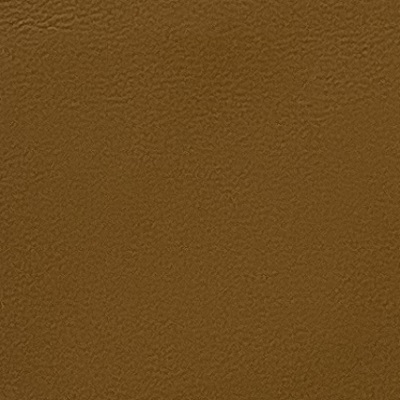

| Shoe inner lining | Shoes,Bags, Clothes |

Another area of innovation in shoe lining technology is the integration of antimicrobial treatments. Footwear linings are susceptible to the growth of odor-causing bacteria and fungi, especially in warm and moist environments. To address this issue, manufacturers are incorporating antimicrobial agents into the lining materials, helping to inhibit the growth of odor-causing microbes and keep the interior of the shoe fresher for longer. This not only enhances wearer comfort but also helps to maintain overall foot health, reducing the risk of infections and other related issues.

In conclusion, innovative techniques in shoe lining technology are revolutionizing the footwear industry, elevating both comfort and durability to new heights. By incorporating moisture-wicking fabrics, enhancing breathability, employing seamless construction methods, and integrating antimicrobial treatments, manufacturers are able to create shoes that not only feel great to wear but also stand the test of time. As consumer expectations continue to evolve, we can expect to see even more exciting advancements in shoe lining technology in the years to come, further enhancing the footwear experience for people around the world.