Table of Contents

Pros and Cons of Using PU Leather for Shoe Manufacturing

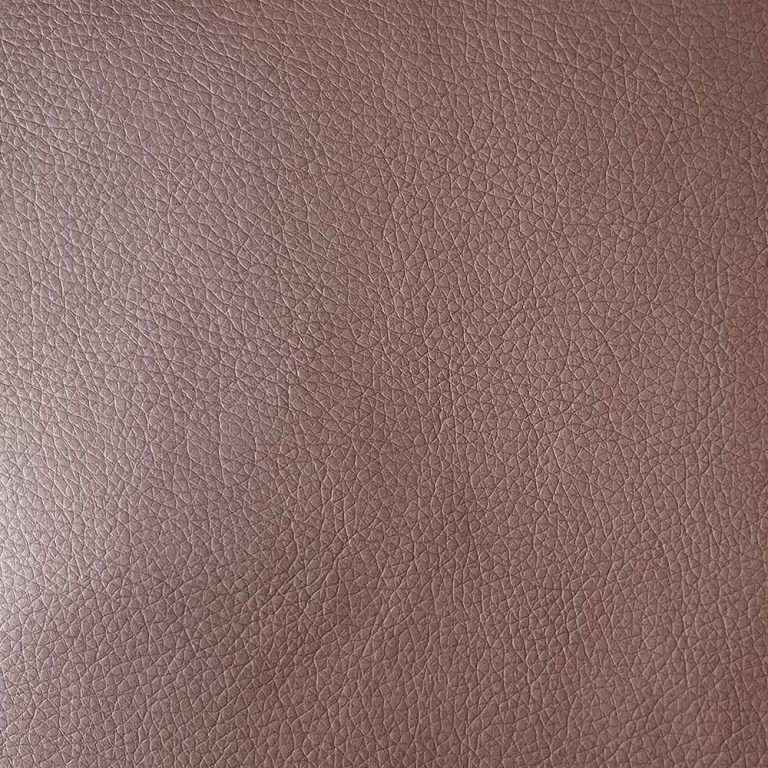

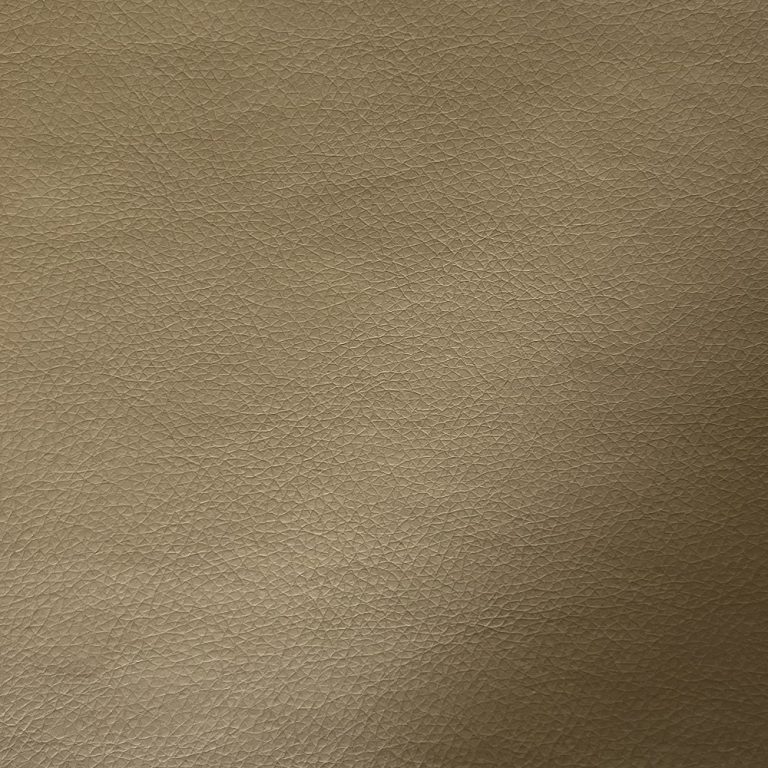

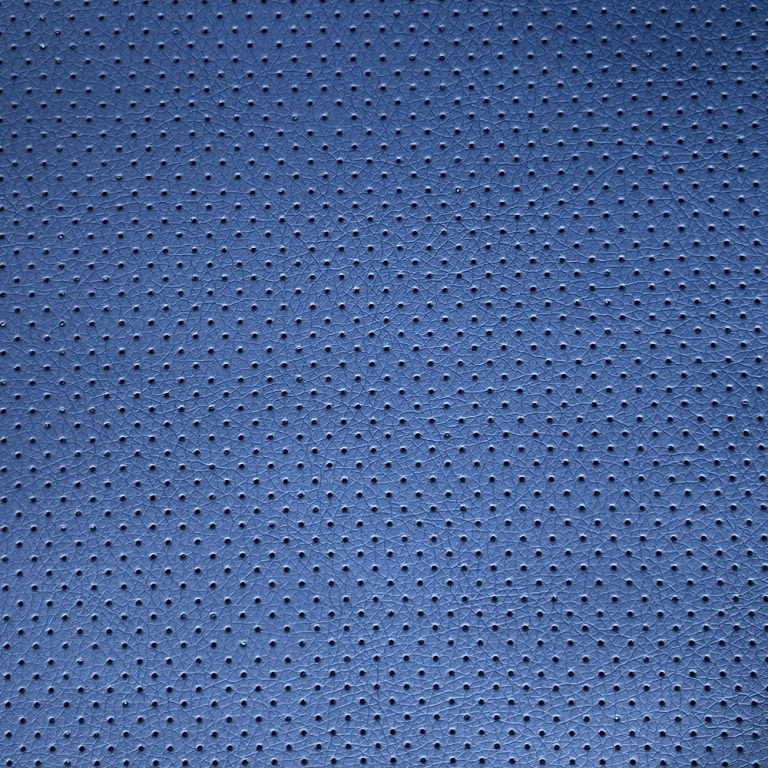

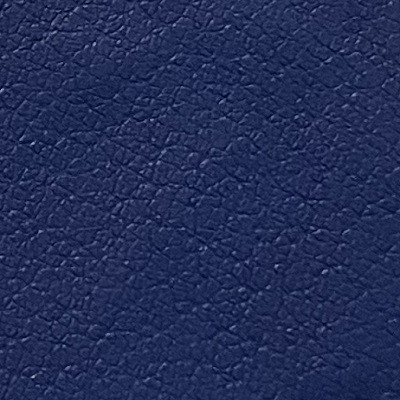

PU leather, also known as polyurethane leather, is a popular material used in the manufacturing of shoes. It is a synthetic material that mimics the look and feel of genuine leather, making it a cost-effective alternative for shoe manufacturers. However, like any material, there are both pros and cons to using PU leather in shoe production.

One of the main advantages of using PU leather for shoes is its affordability. PU leather is much cheaper to produce than genuine leather, making it a cost-effective option for manufacturers looking to keep production costs down. This cost savings can be passed on to consumers, making shoes made from PU leather more affordable for the average person.

In addition to being cost-effective, PU leather is also a versatile material. It can be easily dyed in a wide range of colors, allowing manufacturers to create shoes in a variety of styles and designs. PU leather is also easy to clean and maintain, making it a practical choice for everyday footwear.

Another benefit of using PU leather for shoes is its durability. PU leather is resistant to wear and tear, making it a long-lasting material for shoe production. Shoes made from PU leather are less likely to scuff or scratch, and they can withstand daily use without showing signs of wear.

Despite its many advantages, there are some drawbacks to using PU leather for shoes. One of the main disadvantages is that PU leather is not as breathable as genuine leather. This can lead to sweaty feet and discomfort, especially in hot weather. Additionally, PU leather is not as environmentally friendly as genuine leather, as it is a synthetic material that is not biodegradable.

Another downside to using PU leather for shoes is that it may not have the same luxurious feel as genuine leather. While PU leather can mimic the look of real leather, it may not have the same softness or suppleness. Some consumers may prefer the feel of genuine leather over PU leather, making it a less desirable option for those looking for a high-end shoe.

In conclusion, there are both pros and cons to using PU leather for shoe manufacturing. While PU leather is a cost-effective, versatile, and durable material, it may not be as breathable or luxurious as genuine leather. Ultimately, the decision to use PU leather for shoes will depend on the specific needs and preferences of the manufacturer and consumer.

Sustainable Alternatives to Traditional PU Leather in Shoe Production

PU leather, also known as polyurethane leather, is a popular material used in the production of shoes. It is a synthetic material that mimics the look and feel of genuine leather, making it a cost-effective and versatile option for shoe manufacturers. However, the production of traditional PU leather involves the use of harmful chemicals and processes that can have a negative impact on the environment. As a result, there has been a growing demand for sustainable alternatives to traditional PU leather in shoe production.

One such alternative is the use of plant-based materials as raw materials for PU leather. These materials are derived from renewable sources such as corn, soybeans, and sugarcane, making them a more environmentally friendly option compared to traditional PU leather. Plant-based materials are biodegradable and have a lower carbon footprint, making them a sustainable choice for shoe manufacturers looking to reduce their environmental impact.

Another sustainable alternative to traditional PU leather is the use of recycled materials. Recycled PU leather is made from post-consumer waste such as plastic bottles and other discarded materials. By repurposing these materials, shoe manufacturers can reduce the amount of waste that ends up in landfills and minimize the need for new raw materials. Recycled PU leather is not only environmentally friendly but also helps to promote a circular economy by closing the loop on waste and creating a more sustainable production process.

In addition to plant-based and recycled materials, some shoe manufacturers are exploring the use of alternative materials such as cork, pineapple leaves, and apple peels as raw materials for PU leather. These materials offer unique textures and properties that can enhance the aesthetic appeal of shoes while also providing a sustainable alternative to traditional PU leather. Cork, for example, is a natural material that is harvested from the bark of cork oak trees without harming the tree itself. Pineapple leaves and apple peels are byproducts of the food industry that would otherwise go to waste, making them a sustainable choice for shoe production.

| Product Name | Variety |

| Shoe Upper | S |

While sustainable alternatives to traditional PU leather offer numerous benefits for the environment, there are still challenges that need to be addressed. One of the main challenges is the cost of production, as sustainable materials can be more expensive than traditional PU leather. However, as demand for sustainable products continues to grow, the cost of production is expected to decrease as economies of scale are achieved. Additionally, advancements in technology and innovation are helping to make sustainable materials more affordable and accessible for shoe manufacturers.

Overall, the use of sustainable alternatives to traditional PU leather in shoe production is a positive step towards reducing the environmental impact of the fashion industry. By choosing plant-based, recycled, and alternative materials as raw materials for PU leather, shoe manufacturers can create products that are not only stylish and durable but also environmentally friendly. As consumers become more conscious of the impact of their purchasing decisions, the demand for sustainable shoes is expected to increase, driving further innovation in the industry. With continued research and development, sustainable alternatives to traditional PU leather have the potential to revolutionize the way shoes are made, creating a more sustainable future for the fashion industry.