Table of Contents

Pros and Cons of Using PU Material for Shoe Lining

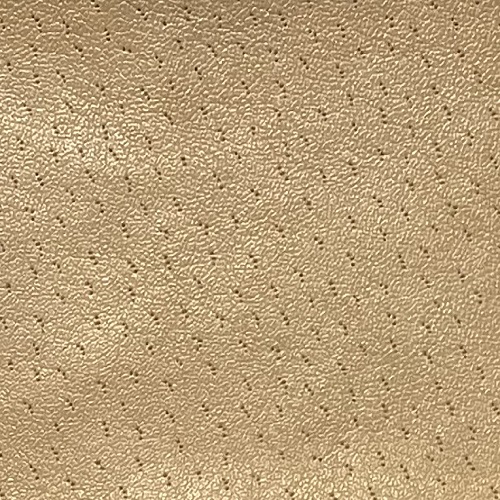

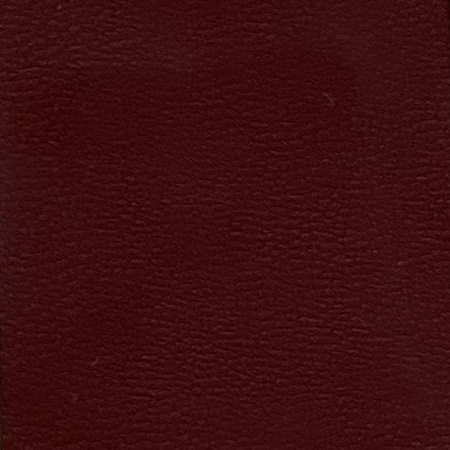

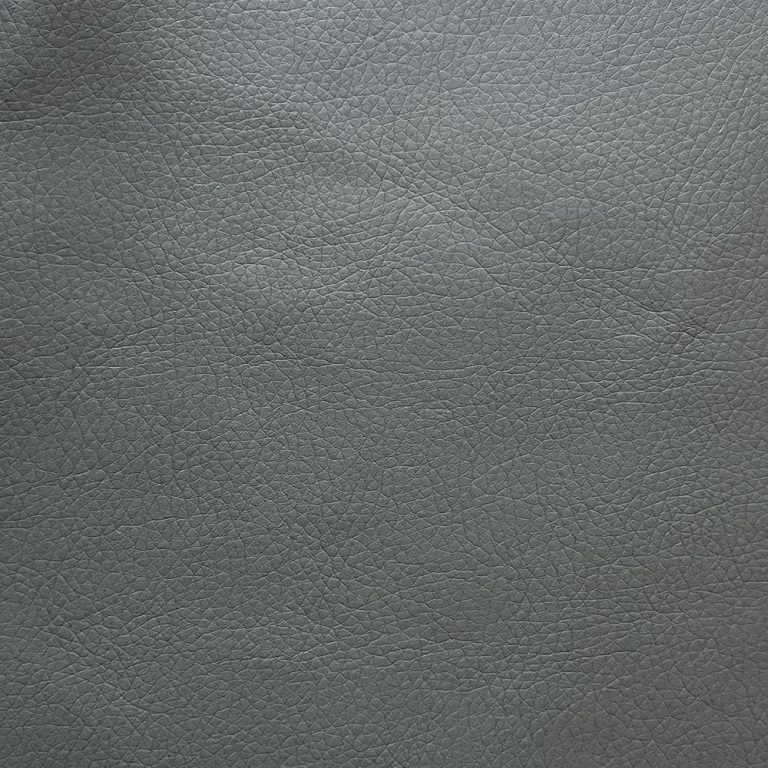

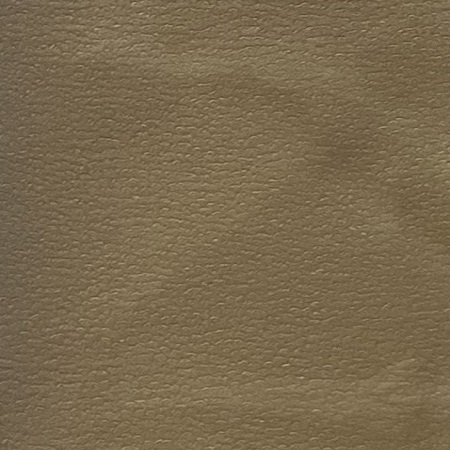

When it comes to choosing materials for shoe lining, polyurethane (PU) is a popular choice among manufacturers. PU is a versatile material that offers a range of benefits for shoe lining applications. However, like any material, there are also some drawbacks to using PU for shoe lining. In this article, we will explore the pros and cons of using PU material for shoe lining.

One of the main advantages of using PU material for shoe lining is its durability. PU is a synthetic material that is known for its strength and resilience. This makes it an ideal choice for shoe lining, as it can withstand the wear and tear that comes with regular use. PU is also resistant to abrasion, making it a long-lasting option for shoe lining.

Another benefit of using PU material for shoe lining is its flexibility. PU is a highly flexible material that can easily conform to the shape of the foot. This makes it comfortable to wear and helps to prevent blisters and discomfort. Additionally, PU is lightweight, which adds to the overall comfort of the shoe.

| Nr. | Name |

| 1 | Shoe lining fabric |

In addition to its durability and flexibility, PU material is also water-resistant. This is an important feature for shoe lining, as it helps to protect the foot from moisture and keeps the shoe dry. PU material is also easy to clean, making it a low-maintenance option for shoe lining.

Despite its many advantages, there are some drawbacks to using PU material for shoe lining. One of the main disadvantages of PU material is that it is not as breathable as natural materials such as leather. This can lead to sweaty feet and discomfort, especially in hot weather. Additionally, PU material can be less environmentally friendly than natural materials, as it is a synthetic material that is not biodegradable.

Another drawback of using PU material for shoe lining is that it can be less comfortable than natural materials. While PU is flexible and lightweight, it may not provide the same level of cushioning and support as materials like leather. This can lead to discomfort and foot pain, especially for those who are on their feet for long periods of time.

In conclusion, there are both pros and cons to using PU material for shoe lining. PU offers durability, flexibility, and water resistance, making it a popular choice among manufacturers. However, PU material may not be as breathable or comfortable as natural materials, and it may not be as environmentally friendly. Ultimately, the decision to use PU material for shoe lining will depend on the specific needs and preferences of the manufacturer and the wearer.

How to Choose the Right PU Manufacturer for Your Shoe Line

When it comes to manufacturing shoes, choosing the right materials is crucial to the success of your shoe line. One important component of a shoe is the lining, which provides comfort and support for the wearer. Polyurethane (PU) is a popular material used for shoe linings due to its durability and flexibility. If you are in the market for a PU manufacturer for your shoe line, there are several factors to consider to ensure you are making the right choice.

First and foremost, it is important to research and vet potential PU manufacturers before making a decision. Look for manufacturers with a proven track record of producing high-quality PU materials for shoes. Check for reviews and testimonials from other clients to get a sense of the manufacturer’s reputation and reliability. Additionally, consider visiting the manufacturer’s facility to see their production process firsthand and ensure they meet your standards for quality and efficiency.

Another important factor to consider when choosing a PU manufacturer for your shoe line is their production capacity. Make sure the manufacturer has the capacity to meet your production needs and deadlines. Discuss your volume requirements with the manufacturer and inquire about their lead times and turnaround times. It is crucial to choose a manufacturer that can accommodate your production schedule and deliver materials in a timely manner to avoid delays in your shoe line.

Cost is also a significant consideration when selecting a PU manufacturer for your shoe line. While it is important to find a manufacturer that offers competitive pricing, it is equally important to consider the quality of the materials they provide. Avoid choosing a manufacturer solely based on price, as lower costs may indicate lower quality materials that could compromise the integrity of your shoe line. Instead, look for a manufacturer that offers a balance of quality and affordability to ensure you are getting the best value for your investment.

Communication is key when working with a PU manufacturer for your shoe line. Make sure the manufacturer is responsive and attentive to your needs and concerns. Clear and open communication is essential to ensure that your specifications and requirements are met throughout the production process. Establishing a strong line of communication with the manufacturer will help prevent misunderstandings and ensure a smooth and successful partnership.

In conclusion, choosing the right PU manufacturer for your shoe line is a critical decision that can impact the quality and success of your products. By researching potential manufacturers, considering their production capacity and pricing, and maintaining open communication, you can find a manufacturer that meets your needs and helps you create a successful shoe line. Take the time to find a reputable and reliable PU manufacturer that aligns with your goals and standards to ensure the success of your shoe line.

The Environmental Impact of PU Shoe Lining Manufacturing

Polyurethane (PU) is a versatile material that is commonly used in the manufacturing of shoe linings. While PU shoe linings offer many benefits, such as durability and water resistance, the production of PU can have a significant environmental impact. In this article, we will explore the environmental impact of PU shoe lining manufacturing and discuss ways in which manufacturers can reduce their environmental footprint.

One of the primary environmental concerns associated with PU shoe lining manufacturing is the use of toxic chemicals. The production of PU involves the use of isocyanates, which are known to be harmful to human health and the environment. Exposure to isocyanates can cause respiratory issues, skin irritation, and other health problems. Additionally, the production of PU can release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and climate change.

In addition to the use of toxic chemicals, the production of PU shoe linings also requires a significant amount of energy. The manufacturing process involves heating and cooling the materials, as well as using machinery to shape and mold the shoe linings. This energy-intensive process contributes to greenhouse gas emissions and exacerbates climate change. Furthermore, the extraction and processing of raw materials for PU production can also have a negative impact on the environment, leading to deforestation, habitat destruction, and water pollution.

Despite these environmental challenges, there are steps that manufacturers can take to reduce the environmental impact of PU shoe lining manufacturing. One approach is to invest in more sustainable production methods, such as using renewable energy sources and implementing energy-efficient technologies. By reducing energy consumption and greenhouse gas emissions, manufacturers can minimize their environmental footprint and contribute to a more sustainable future.

Another way to reduce the environmental impact of PU shoe lining manufacturing is to use alternative materials that are less harmful to the environment. For example, some manufacturers are exploring the use of bio-based materials, such as plant-based polymers, as a more sustainable alternative to traditional PU. By using materials that are derived from renewable sources, manufacturers can reduce their reliance on fossil fuels and minimize their impact on the environment.

Furthermore, manufacturers can also take steps to improve the recycling and disposal of PU shoe linings. By designing products that are easier to recycle and implementing recycling programs, manufacturers can reduce the amount of waste that ends up in landfills. Additionally, manufacturers can work with suppliers to ensure that the raw materials used in PU production are sourced responsibly and sustainably.

In conclusion, the production of PU shoe linings can have a significant environmental impact, from the use of toxic chemicals to the consumption of energy and resources. However, by implementing more sustainable production methods, using alternative materials, and improving recycling practices, manufacturers can reduce their environmental footprint and create a more sustainable future for the footwear industry. It is essential for manufacturers to prioritize environmental sustainability in their production processes and work towards minimizing their impact on the planet.