Table of Contents

Sustainable Practices in Shoe PU Factory

Sustainable Practices in Shoe PU Factory

In recent years, there has been a growing emphasis on sustainability in the manufacturing industry. This shift towards more environmentally friendly practices has also extended to the shoe manufacturing sector, with many companies looking for ways to reduce their carbon footprint and minimize their impact on the environment. One area where sustainable practices are particularly important is in the production of polyurethane (PU) shoes.

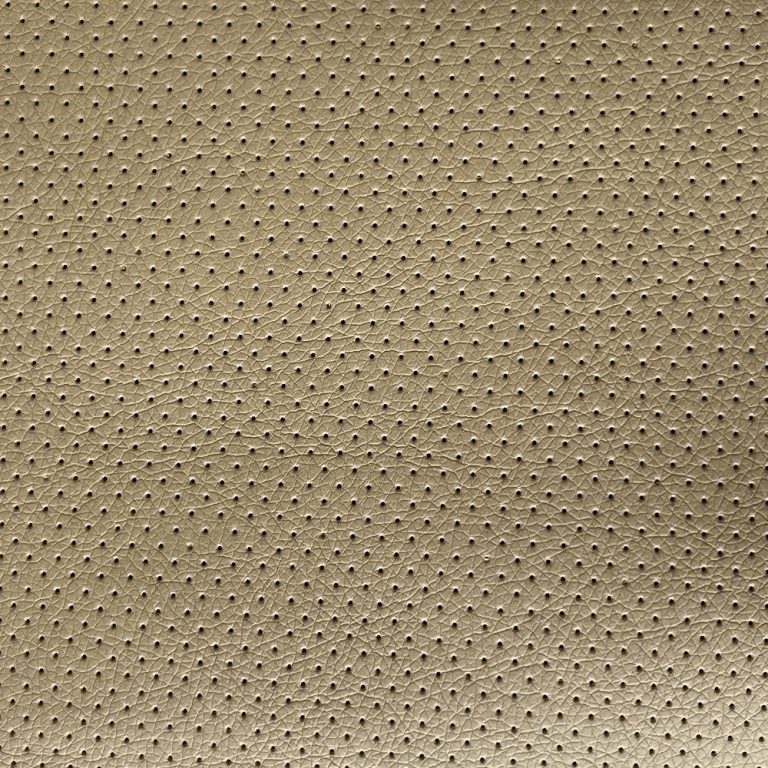

PU is a versatile material that is commonly used in the production of shoes due to its durability and flexibility. However, the production of PU can be harmful to the environment if not done responsibly. Many shoe PU factories have recognized this and are taking steps to implement sustainable practices in their production processes.

One of the key ways in which shoe PU factories are becoming more sustainable is by reducing their use of harmful chemicals. Many of the chemicals used in the production of PU can be toxic to both humans and the environment. By using alternative, less harmful chemicals, shoe factories can minimize their impact on the environment and create a safer working environment for their employees.

Another important aspect of sustainability in shoe PU factories is the reduction of waste. The production of PU shoes can generate a significant amount of waste, including offcuts and scraps of material. By implementing recycling programs and finding ways to reuse these materials, shoe factories can reduce the amount of waste they send to landfills and minimize their overall environmental impact.

Energy efficiency is also a key focus for many shoe PU factories looking to become more sustainable. By investing in energy-efficient equipment and implementing practices to reduce energy consumption, factories can lower their carbon emissions and reduce their overall environmental footprint. This not only benefits the environment but can also lead to cost savings for the factory in the long run.

In addition to reducing their environmental impact, many shoe PU factories are also looking for ways to support their local communities and promote social responsibility. This can include initiatives such as providing fair wages and safe working conditions for employees, as well as supporting local charities and community projects. By investing in their communities, shoe factories can create a positive impact beyond their own operations.

| Nr. | Product |

| 1 | Shoe Upper |

Overall, the shift towards sustainability in shoe PU factories is a positive development for both the industry and the environment. By implementing sustainable practices, factories can reduce their environmental impact, create a safer working environment for employees, and support their local communities. As consumers become more conscious of the environmental and social impact of the products they buy, sustainable practices in shoe manufacturing will only become more important. By embracing sustainability, shoe PU factories can not only reduce their carbon footprint but also create a more ethical and responsible business model for the future.

Advancements in Technology for Shoe PU Manufacturing

Advancements in Technology for Shoe PU Manufacturing

Polyurethane (PU) is a versatile material that has become increasingly popular in the shoe manufacturing industry. Its durability, flexibility, and lightweight properties make it an ideal material for producing high-quality footwear. With the advancements in technology, shoe PU factories are now able to produce shoes more efficiently and with greater precision than ever before.

One of the key advancements in technology for shoe PU manufacturing is the use of computer-aided design (CAD) software. This software allows designers to create detailed 3D models of shoes, which can then be used to program automated manufacturing machines. By using CAD software, shoe factories can streamline the design process, reduce errors, and produce shoes with greater accuracy.

Another important technological advancement in shoe PU manufacturing is the use of robotic automation. Robots are now being used in shoe factories to perform a variety of tasks, such as cutting, stitching, and gluing. By using robots, shoe manufacturers can increase production speed, improve quality control, and reduce labor costs. Additionally, robots can work around the clock, allowing shoe factories to operate more efficiently and meet tight production deadlines.

In addition to CAD software and robotic automation, shoe PU factories are also utilizing advanced materials and processes to improve the quality of their products. For example, some factories are now using 3D printing technology to create custom insoles and outsoles for shoes. This allows for greater customization and personalization, as well as improved comfort and support for the wearer.

Furthermore, shoe PU factories are also investing in sustainable manufacturing practices. By using eco-friendly materials and processes, shoe manufacturers can reduce their environmental impact and appeal to environmentally conscious consumers. Some factories are now using recycled PU materials, such as old shoes or industrial waste, to create new shoes. This not only reduces waste but also conserves resources and lowers production costs.

Overall, the advancements in technology for shoe PU manufacturing have revolutionized the industry and allowed for greater innovation and efficiency. By using CAD software, robotic automation, advanced materials, and sustainable practices, shoe factories are able to produce high-quality shoes that meet the demands of today’s consumers. As technology continues to evolve, we can expect to see even more exciting developments in the field of shoe manufacturing.