Pros and Cons of Using PU Microfiber Leather for Shoe Manufacturing

PU microfiber leather has become a popular material in the shoe manufacturing industry due to its many benefits. This synthetic material is made from polyurethane, which is a versatile and durable substance that can mimic the look and feel of genuine leather. In this article, we will explore the pros and cons of using PU microfiber leather for shoe production.

One of the main advantages of using PU microfiber leather is its affordability. Compared to genuine leather, PU microfiber leather is much more cost-effective, making it a popular choice for manufacturers looking to reduce production costs. Additionally, PU microfiber leather is a vegan-friendly alternative to genuine leather, making it a more sustainable option for environmentally conscious consumers.

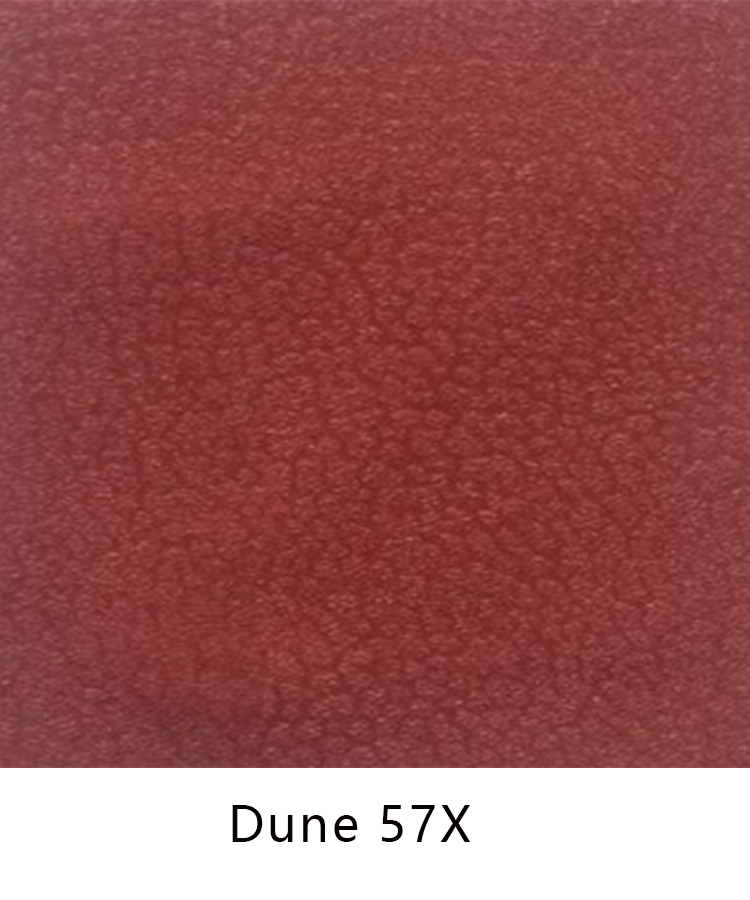

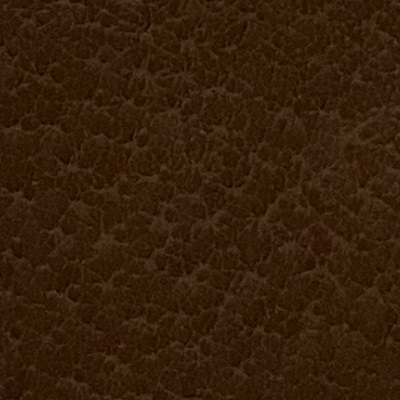

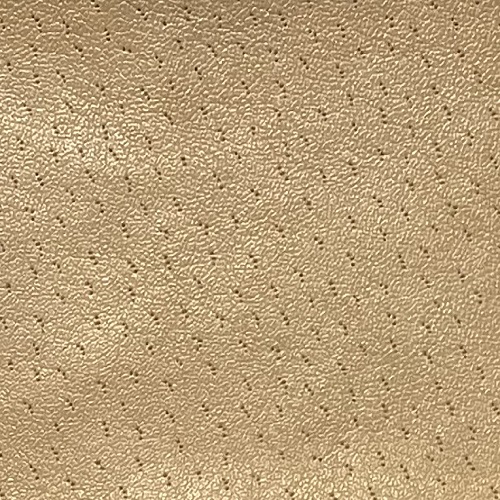

Another benefit of using PU microfiber leather for shoe manufacturing is its versatility. This material can be easily dyed and embossed, allowing for a wide range of design options. Manufacturers can create shoes in various colors and textures, giving them the flexibility to cater to different consumer preferences. Additionally, PU microfiber leather is lightweight and flexible, making it a comfortable choice for footwear.

| Nr. | Commodity Name |

| 1 | Shoe Upper |

In terms of durability, PU microfiber leather is a strong and long-lasting material. It is resistant to wear and tear, making it a suitable option for shoes that are subjected to daily use. PU microfiber leather is also easy to clean and maintain, requiring minimal upkeep to keep it looking new. This durability makes PU microfiber leather a practical choice for consumers looking for shoes that will last a long time.

Despite its many advantages, there are some drawbacks to using PU microfiber leather for shoe manufacturing. One of the main concerns is that PU microfiber leather is not as breathable as genuine leather. This can lead to discomfort for some wearers, especially in hot and humid conditions. Additionally, PU microfiber leather may not have the same natural feel as genuine leather, which can be a drawback for consumers who prefer the look and texture of real leather.

Another potential downside of using PU microfiber leather is its environmental impact. While PU microfiber leather is a more sustainable option than genuine leather in terms of animal welfare, it is still a synthetic material that requires the use of chemicals in its production. This can have negative consequences for the environment, especially if these chemicals are not properly disposed of. Additionally, the production of PU microfiber leather may contribute to pollution and waste, further impacting the environment.

In conclusion, PU microfiber leather offers many benefits for shoe manufacturing, including affordability, versatility, and durability. However, there are also some drawbacks to consider, such as breathability issues and environmental concerns. Ultimately, the decision to use PU microfiber leather for shoe production will depend on the specific needs and preferences of the manufacturer and consumer. By weighing the pros and cons of this material, manufacturers can make an informed decision about whether PU microfiber leather is the right choice for their footwear products.