Table of Contents

Benefits of Using Leather in Shoe Manufacturing

Leather has been a popular material for shoe manufacturing for centuries, and for good reason. There are numerous benefits to using leather in the production of shoes, ranging from its durability and comfort to its aesthetic appeal and environmental sustainability.

One of the primary advantages of using leather in shoe manufacturing is its durability. Leather is a strong and resilient material that can withstand the wear and tear of daily use, making it an ideal choice for footwear that needs to last. Shoes made from leather are less likely to tear or break down compared to those made from synthetic materials, ensuring that they will remain in good condition for a longer period of time.

In addition to its durability, leather is also known for its comfort. Leather shoes are soft and flexible, molding to the shape of the wearer’s foot over time to provide a custom fit. This makes leather shoes more comfortable to wear for extended periods, reducing the risk of blisters and other foot-related issues. The breathability of leather also helps to regulate temperature and moisture, keeping the feet cool and dry throughout the day.

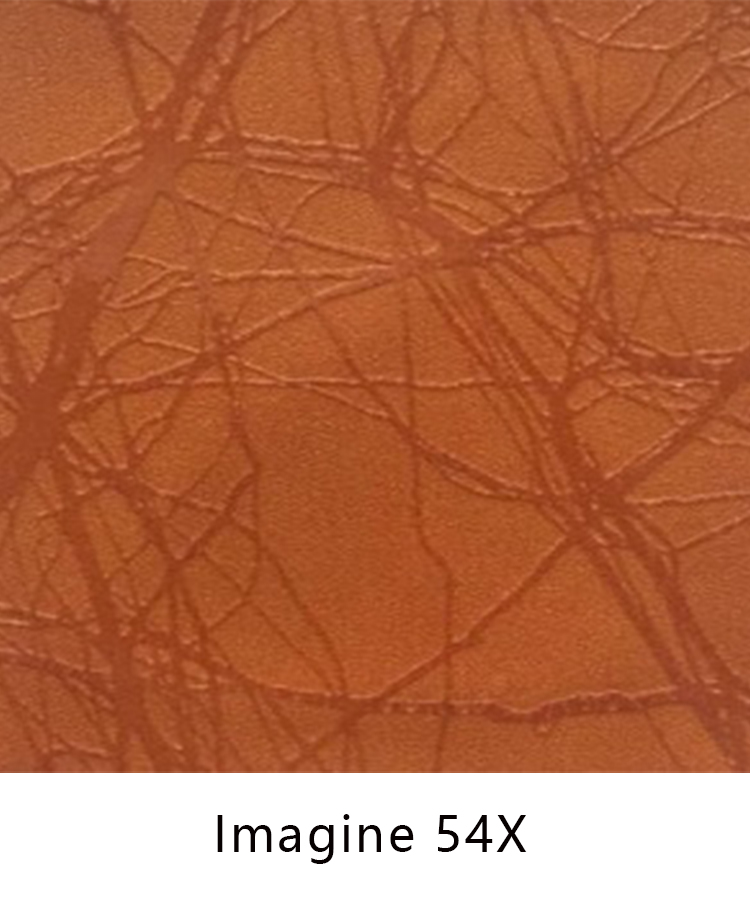

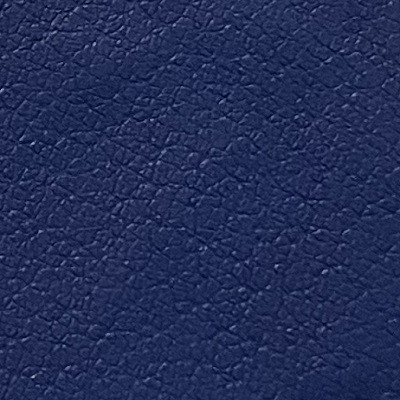

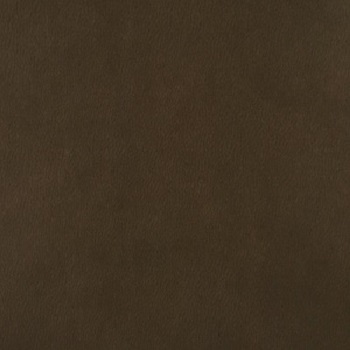

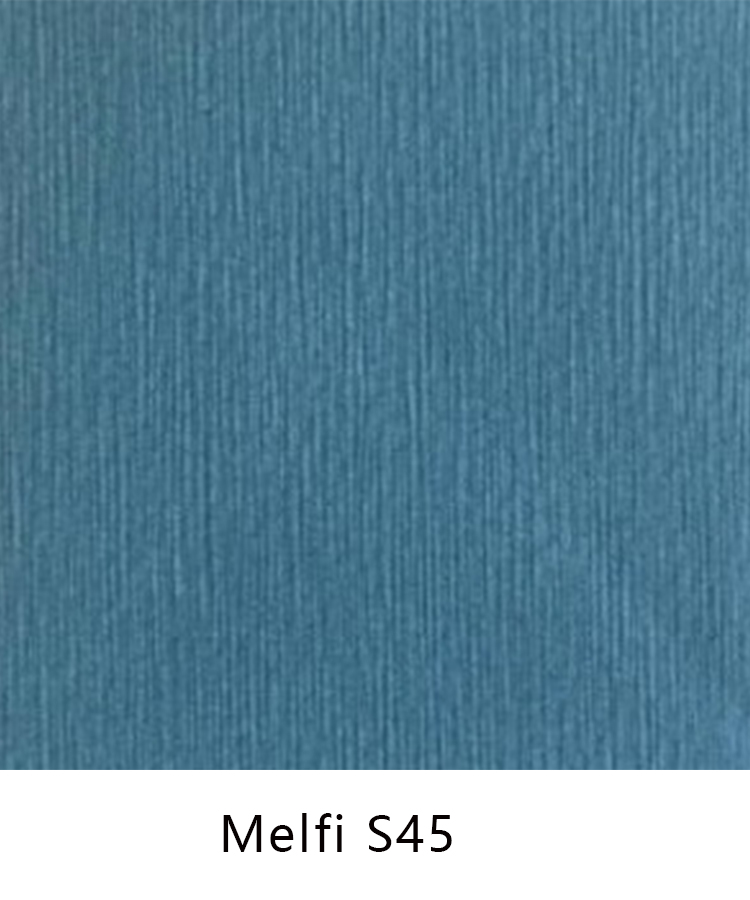

Another benefit of using leather in shoe manufacturing is its aesthetic appeal. Leather has a timeless and classic look that adds a touch of sophistication to any outfit. Whether it’s a sleek pair of leather dress shoes or a rugged pair of leather boots, leather footwear is versatile and stylish, making it a popular choice for both formal and casual occasions. The natural grain and texture of leather also give shoes a unique and luxurious appearance that sets them apart from other materials.

From an environmental standpoint, leather is a sustainable and eco-friendly choice for shoe manufacturing. Leather is a natural material that is biodegradable and renewable, making it a more environmentally friendly option compared to synthetic materials that are derived from petrochemicals. Additionally, leather production can be done in a way that minimizes waste and pollution, further reducing its impact on the environment.

In conclusion, there are many benefits to using leather in shoe manufacturing. From its durability and comfort to its aesthetic appeal and environmental sustainability, leather is a versatile and practical material that has stood the test of time. Whether you’re looking for a durable and stylish pair of dress shoes or a comfortable and breathable pair of sneakers, leather footwear is a great choice that will not disappoint. So next time you’re in the market for a new pair of shoes, consider opting for leather – you won’t be disappointed.

A Behind-the-Scenes Look at a Shoe Leather Factory

A shoe leather factory is a fascinating place where raw materials are transformed into high-quality leather that is used to make shoes. The process of turning animal hides into leather is a complex one that requires skill, precision, and attention to detail. In this article, we will take a behind-the-scenes look at a shoe leather factory to see how this transformation takes place.

| Commodity Name | Use |

| Shoe Upper | Shoes |

The first step in the process of making leather is to source high-quality animal hides. These hides are typically obtained from cows, sheep, or goats, and must be carefully inspected to ensure that they are free from defects. Once the hides have been selected, they are soaked in a solution of water and chemicals to remove any dirt, blood, or other impurities.

After soaking, the hides are then treated with a mixture of chemicals to help break down the proteins in the skin and make it more pliable. This process, known as tanning, can take several days to complete and requires careful monitoring to ensure that the hides are not over- or under-treated.

Once the tanning process is complete, the hides are stretched and dried to remove excess moisture. They are then shaved to remove any remaining hair or flesh, and dyed to the desired color. The hides are then treated with oils and waxes to make them soft, supple, and water-resistant.

The final step in the leather-making process is to finish the leather. This involves buffing the surface to remove any imperfections, and applying a protective coating to help preserve the leather and give it a glossy finish. The finished leather is then ready to be used in the production of shoes.

In a shoe leather factory, the finished leather is cut into pieces according to a pattern, and stitched together to create the upper part of the shoe. The sole of the shoe is typically made from a different type of leather that is thicker and more durable. Once the upper and sole have been assembled, the shoe is shaped and molded to give it its final form.

After the shoes have been assembled, they are inspected for quality and any defects are repaired. The shoes are then polished and buffed to give them a shiny finish, and packaged for shipment to retailers.

Working in a shoe leather factory requires a high level of skill and attention to detail. Leather workers must be able to identify different types of leather and understand how each type should be treated. They must also be able to operate machinery such as cutting and stitching machines, and work quickly and efficiently to meet production deadlines.

In conclusion, a shoe leather factory is a place where raw materials are transformed into high-quality leather that is used to make shoes. The process of making leather is a complex one that requires skill, precision, and attention to detail. By taking a behind-the-scenes look at a shoe leather factory, we can gain a greater appreciation for the craftsmanship and dedication that goes into making a pair of shoes.