Table of Contents

Pros and Cons of Using PU Leather for Sofa Manufacturing

When it comes to choosing the material for your sofa, there are a variety of options available on the market. One popular choice is PU leather, also known as faux leather or synthetic leather. PU leather is a synthetic material that is designed to look and feel like real leather, but at a fraction of the cost. While PU leather has its advantages, there are also some drawbacks to consider when using it for sofa manufacturing.

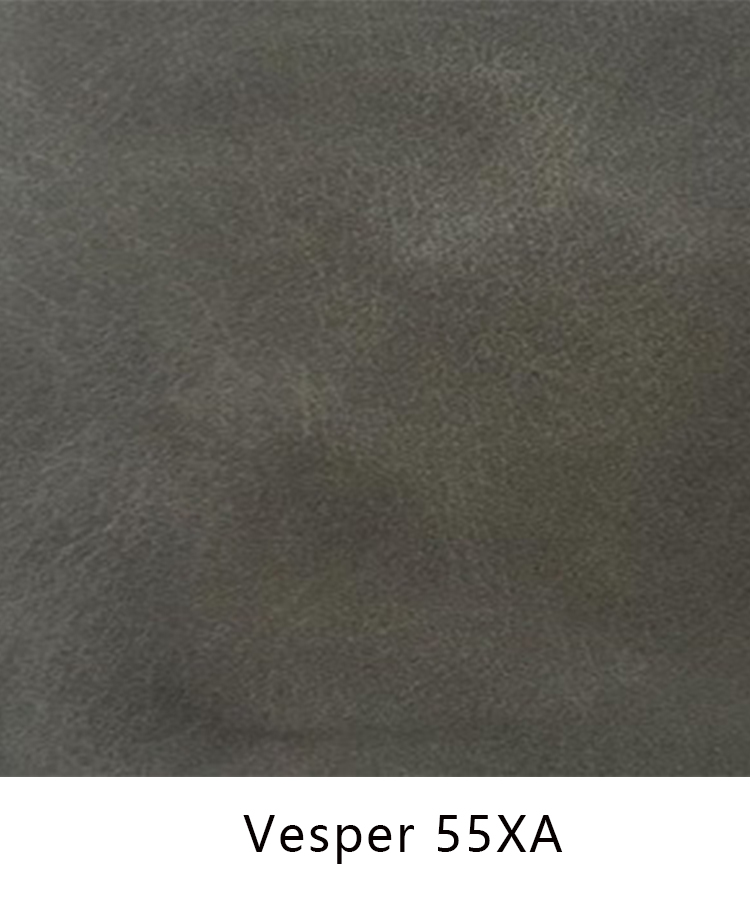

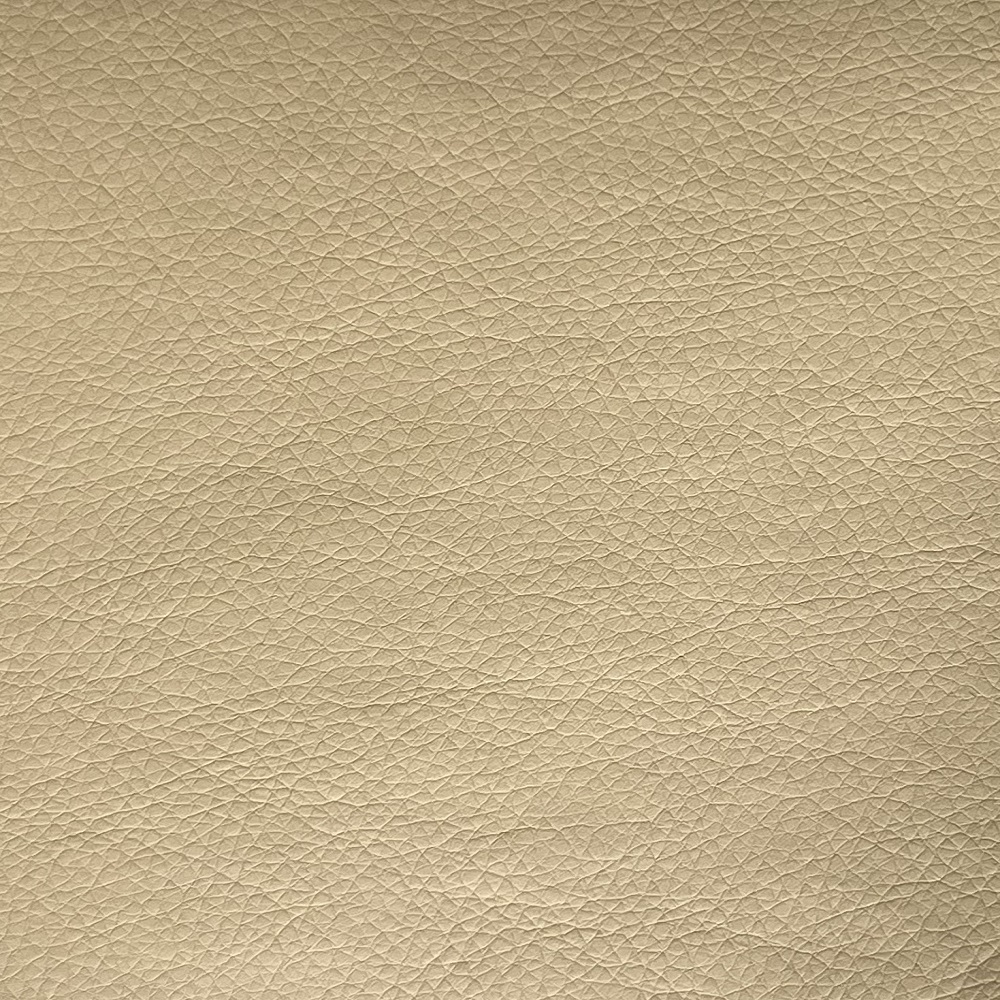

One of the main advantages of using PU leather for sofa manufacturing is its affordability. PU leather is typically much cheaper than genuine leather, making it a more budget-friendly option for consumers. This can be especially appealing for those who want the look of leather without the high price tag. Additionally, PU leather is available in a wide range of colors and finishes, allowing for greater customization and design options for sofas.

Another benefit of using PU leather for sofa manufacturing is its durability. PU leather is resistant to stains, scratches, and fading, making it a practical choice for households with children or pets. Additionally, PU leather is easy to clean and maintain, requiring only a damp cloth to wipe away spills and dirt. This can save time and effort in the long run, as PU leather sofas require less maintenance than genuine leather sofas.

However, there are some drawbacks to using PU leather for sofa manufacturing. One of the main concerns is that PU leather is not as breathable as genuine leather, which can make it less comfortable to sit on for extended periods of time. PU leather can also be prone to peeling and cracking over time, especially if it is exposed to harsh sunlight or high temperatures. This can detract from the overall appearance and longevity of the sofa.

Additionally, some consumers may have ethical concerns about using PU leather, as it is a synthetic material that is not biodegradable. While PU leather is often considered a more sustainable option than genuine leather, it still has environmental impacts that should be taken into consideration. Some consumers may prefer to choose a more eco-friendly material for their sofas, such as recycled or organic fabrics.

In conclusion, there are both pros and cons to using PU leather for sofa manufacturing. While PU leather is affordable, durable, and customizable, it may not be as comfortable or environmentally friendly as other materials. Ultimately, the decision to use PU leather for sofa manufacturing will depend on individual preferences and priorities. By weighing the advantages and disadvantages of PU leather, consumers can make an informed choice when selecting a sofa for their home.

How to Choose the Right Sofa PU Manufacturer for Your Business

When it comes to running a successful business in the furniture industry, choosing the right sofa PU manufacturer is crucial. The quality of the products you offer to your customers can make or break your reputation, so it’s important to do your due diligence when selecting a manufacturer to partner with. In this article, we will discuss some key factors to consider when choosing a sofa PU manufacturer for your business.

| Products | Sort |

| PU Leather for sofa | S |

First and foremost, it’s essential to research potential manufacturers thoroughly. Look for companies with a solid reputation in the industry, as well as a track record of producing high-quality products. Reading customer reviews and testimonials can give you valuable insight into the manufacturer’s reliability and customer satisfaction levels. Additionally, consider visiting the manufacturer’s facility in person to see their operations firsthand and ensure they meet your standards.

Another important factor to consider when choosing a sofa PU manufacturer is their production capacity. Make sure the manufacturer has the capability to meet your business’s demands in terms of volume and lead times. You don’t want to partner with a manufacturer who can’t keep up with your orders, as this can lead to delays and ultimately impact your bottom line. Ask about the manufacturer’s production capabilities and lead times upfront to avoid any surprises down the line.

In addition to production capacity, it’s also important to consider the manufacturer’s quality control processes. A reputable manufacturer will have strict quality control measures in place to ensure that every product meets your specifications and standards. Ask about the manufacturer’s quality control procedures, including how they inspect materials, monitor production processes, and test finished products. Choosing a manufacturer with a strong focus on quality control can help you avoid costly issues such as defects and returns.

Cost is another crucial factor to consider when choosing a sofa PU manufacturer for your business. While it’s important to find a manufacturer that offers competitive pricing, it’s equally important not to sacrifice quality for cost. Remember that the cheapest option isn’t always the best option, as low prices can sometimes indicate subpar materials or workmanship. Consider the overall value that the manufacturer offers, taking into account factors such as quality, reliability, and customer service in addition to pricing.

Communication is key when working with a sofa PU manufacturer, so be sure to choose a manufacturer that is responsive and easy to work with. Clear and open communication is essential for ensuring that your needs and expectations are met throughout the manufacturing process. Look for a manufacturer that is willing to listen to your feedback, address any concerns or issues promptly, and keep you informed of progress updates. A manufacturer who values communication and collaboration can help you build a strong and successful partnership.

In conclusion, choosing the right sofa PU manufacturer for your business is a decision that should not be taken lightly. By considering factors such as reputation, production capacity, quality control, cost, and communication, you can make an informed decision that will benefit your business in the long run. Take the time to research potential manufacturers, ask questions, and visit facilities to ensure that you find a partner who meets your needs and aligns with your business goals. With the right manufacturer by your side, you can offer high-quality products to your customers and build a successful and reputable furniture business.